Welcome to our AKMHS Official Pallet Rack Guide. Here you can find everything you need to know about pallet rack systems and related products. We’re continually adding to and updating this information to make it as accurate and helpful as possible, but always recommend that you contact the pallet rack manufacturer for the most accurate information about your pallet rack system.

See our most recent Pallet Rack Identifier here or at the bottom of this page for help identifying your current rack configurations.

If you have any specific questions about your pallet rack systems, or need warehouse layout design help please call one of our pallet rack sales or design experts at 800-722-5908.

Pallet Racks

Pallet Rack is a material handling storage system engineered to store materials and products that are packaged on pallets or skids. There are many different styles and manufacturers of pallet racking, but all of these share the same goal: increasing storage density by storing pallets off of the ground and utilizing vertical space. Pallets or other materials are loaded onto pallet racks with fork trucks chosen specifically for the application. Dating back to the early patents of “pallet rack US 2577276” circa 1948, pallet racking has been among the most widely used material storage systems in large warehouses, distribution centers, manufacturing plants, and other storage facilities.

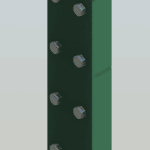

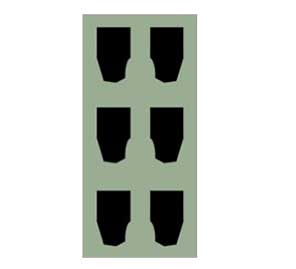

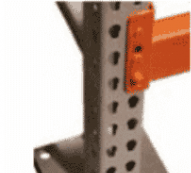

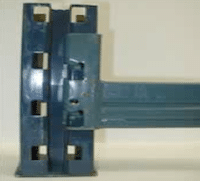

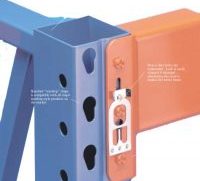

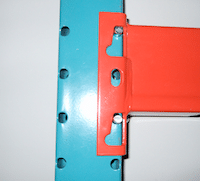

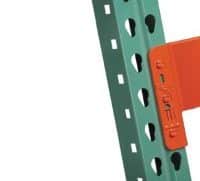

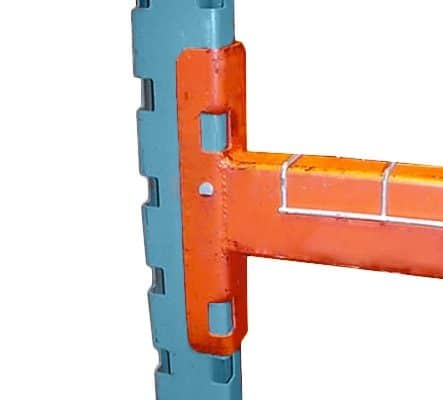

Each manufacturer makes racking in a slightly different style. The beam-to-frame connection and punch hole style is what differentiates the styles. Among these styles, the teardrop selective design is the most common by far. Teardrop racking is named after the teardrop-shaped punch holes on the upright frame. Most teardrop racking is universal and can be mixed with other systems although it is not typically recommended. View our Pallet Rack Identifier at the bottom of the page to see which style or manufacturer you pallet rack is.

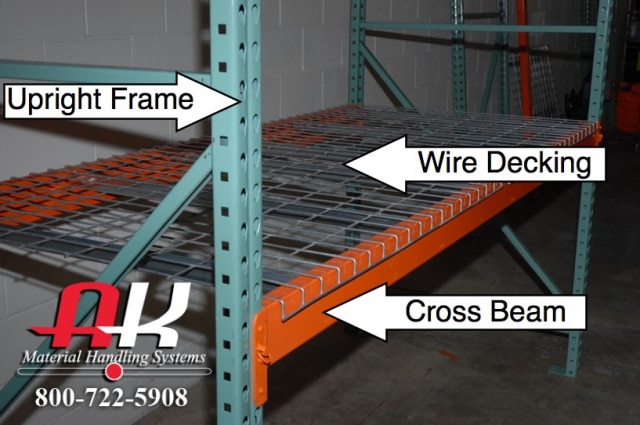

Pallet Rack Components

The three primary components of a pallet rack system are frames, beams, and wire decks. Read more about each of these components below.

Upright Frames

Upright Frames – frames are also known as upright columns. Frames connect to the horizontal beams to create a pallet rack system. Upright frames are manufactured with punch holes (often shaped like a teardrop) all along the column, so the beam connectors can be installed at any height depending on the application. Frames are manufactured with either structural or roll-formed steel.

Cross Beam

Cross beam — beams are the horizontal bars that connect to the upright frames, creating a sturdy shelf level to store pallets on. They come in numerous lengths with different capacity ratings and are manufactured from either structural or roll-formed steel.

Wire Decking

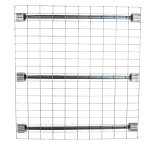

Wire Decking – is often used as a safety measure for the pallets being stored in the pallet rack system. Decking not only creates a safety measure for the rack system by expanding surface area but also allows for better air circulation and the flow of water from sprinkler systems.

Styles of Wire Decking

There are many different styles of wire decking that may perform better in different applications. See the most common wire deck styles below. In addition to these three styles, there is corrugated decking and punch deck that is discussed in the pallet rack accessories section later on in the page.

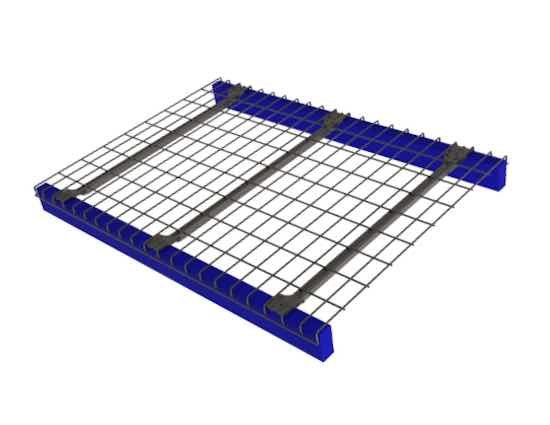

Flanged/Universal

Used on pallet rack box beams (beams with no inside step), structural rack and selective systems. As its name suggests, universal/flare channel decks can be used on almost any type of pallet rack cross beam.

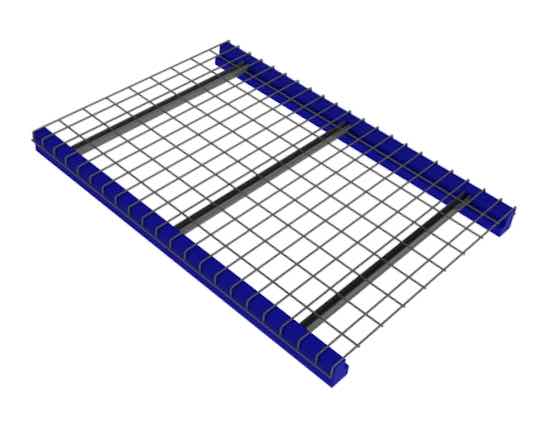

U Channel Standard

U Channel Standard decks are used on standard pallet rack beams that have a traditional step measuring 1 5/8” U Channel decks are stronger than their flare channel counterparts, but cannot be used on beams that don’t have an inside step for the support channel.

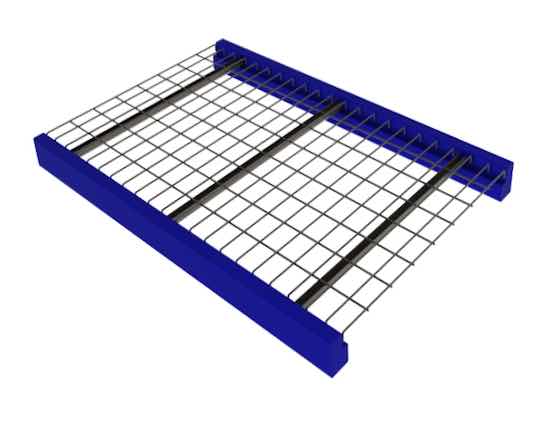

Inside Waterfall

Used on pallet rack in applications where the beam face needs to be open for barcoding or capacity labels. As seen in the image, the waterfall extends down on the inside of the beam, as opposed to the outer beam face.

Pallet Rack Specifications

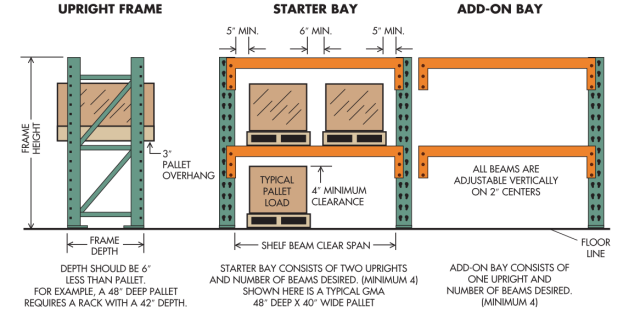

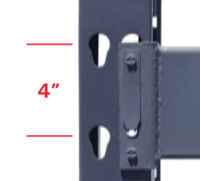

Upright Frame – To determine the proper frame height for your pallet rack system, perform this calculation: Frame height= (height of pallet + height of beam+ 4” vertical clearance) x number of levels

Cross Beam – The correct beam length for your application is calculated by adding the widths of the pallet loads plus a 5″ side clearance between upright and pallet, and 6″ between pallet loads (see image left).

Wire Mesh Decking – Wire decking provides added safety to your rack system. Our wire decking manufacturers are seperate from our pallet rack manufacturers, and the size of your decking will depend on the size of the pallet rack system.

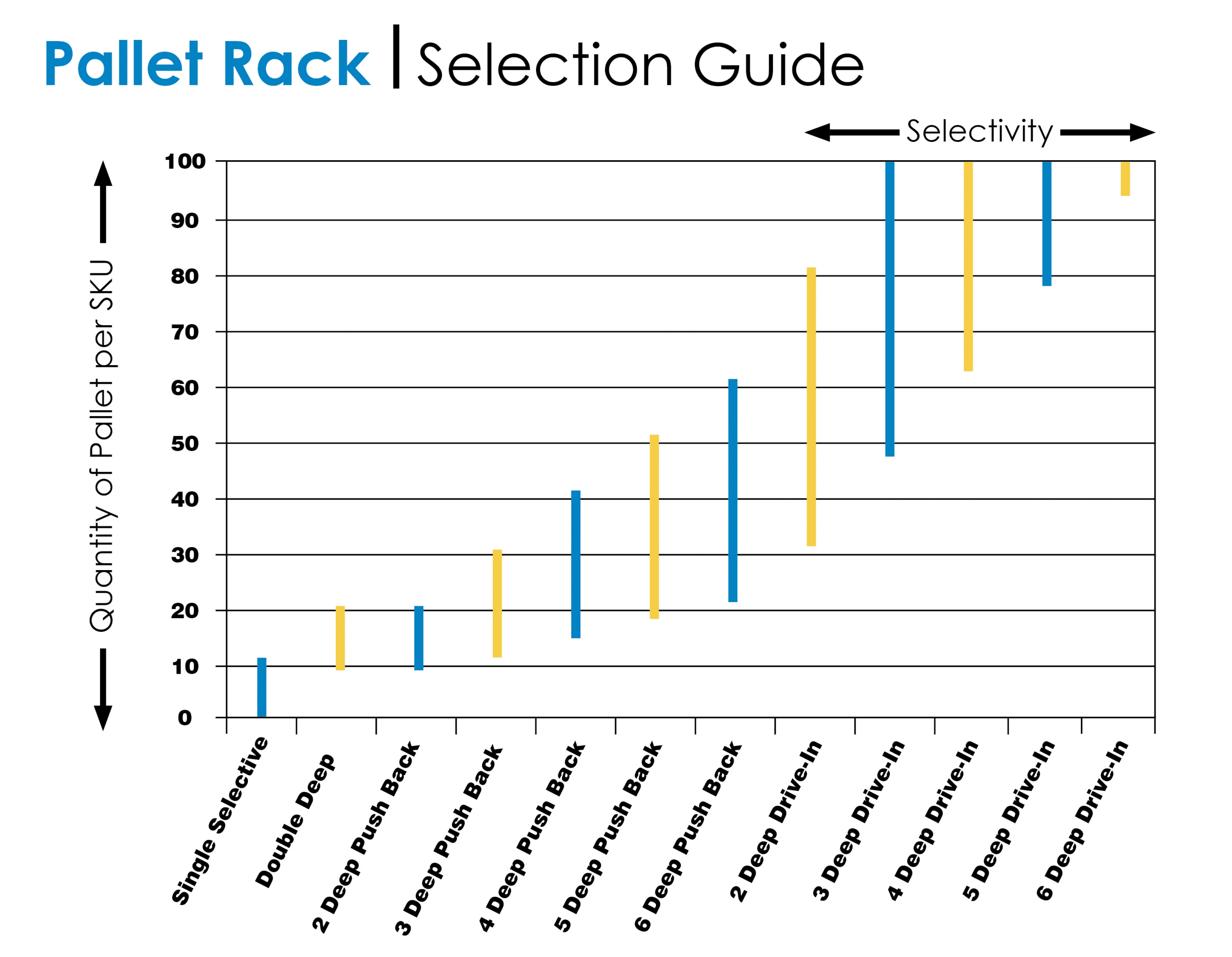

Pallet Rack Selection Guide

One of our manufacturers, Advance, created this table to help buyers make the right decisions for their warehouse’s inventory/application. The quantity of pallets per SKU is a major deciding factor for the type of pallet rack system to choose. Look at the chart to the right to learn what rack system and configuration may be best for your application.

Pallet Rack Accessories

Pallet rack accessories are complementary components that serve unique purposes in a pallet rack system. Here are some of the most common accessories and how they are used:

Dividers

Hanging Shelf Divider

These are used on pallet rack shelves to separate the contents of a beam level. These dividers work by hanging from the above decking and connecting to the deck at the bottom on the beam level.

Standing Shelf Divider

Used in pallet rack shelves to create separation on a beam level. These simply clip into the wire decking on the beam level and secure themselves in place.

Flue Spacer

Used on wire decking to create a flue space. Flue spaces are often a necessary requirement in local fire and safety codes, as they allow fires to vent vertically and the water from sprinkler systems to reach the fire’s source.

General Accessories

Row Spacer

Row spacers keep back-to-back rows of pallet racking steady and aligned. They are often required to maintain enough flue space between your racking.

Shim

Pallet rack shims go beneath the footplates of racking on uneven ground. They help to level and stabilize the system.

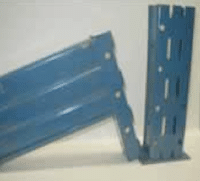

Splice Channel

A pallet rack splice channel or column splice kit allows two frames to be spliced together, one on top of the other. This is how pallet rack systems gain height for additional beam levels.

Pallet Rack Anchor

Anchor bolts for pallet racking, or wedge anchors, secure pallet rack uprights directly to concrete warehouse floors. Pallet rack anchoring is always recommended and required by most cities.

Wall Tie

Pallet rack wall ties bolt into warehouse walls, keeping single rows of pallet racking secured and aligned against the wall.

Drum Bed

Pallet rack drum beds or drum coil beds attach to pallet rack beams to store drums or other cylindrical objects.

Drum Cradle

Pallet rack drum cradles attach to the upright columns and allow pallet racks to store large reels.

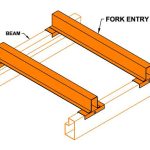

Fork Entry Bar

Fork entry bars or fork clearance bars allow forklifts to access non-palletized flat stock storage. These bars create a 2 1/2″ gap between the beam and the inventory so the forklift can easily enter and lift the product.

Decking

Corrugated Decking

Corrugated decks are a type of solid steel decking used on pallet racks to create a shelf that is flush with the beam for smooth product loading and unloading.

Wire Mesh Deck

Wire mesh decks are made of welded wire that rests on the beams of the racking system, creating a shelf level for added protection from falling pallets or products. Most wire decks have support channels welded on the bottom of the wire for increased load support capacity.

Pallet Supports

Pallet supports are pallet rack safety bars that attach from one beam to another and provide additional support to stored pallets. They can be used alone or in tandem with wire decking.

Punch Deck (Dacs)

A punch deck is a flat, heavy-duty steel decking option perforated with a series of holes. These holes allow air, light, and water through the decks to safely store a wide variety of products.

Particle Board Decking

Particle board decking is a light-duty flat surface option typically used for steel shelving or boltless racking.

Safety Products

Column Guard

Column guards or column protectors are anchored to the floor or bolted to the front of the pallet rack upright frame, protecting it from forklift damage.

Angle Deflectors (Bolt-On or Welded)

Angle deflectors are a type of column guard that can be welded onto the frame during manufacturing or bolted on as an accessory. Pallet rack angle deflectors are designed to deflect impact and are placed on upright frames in areas susceptible to damage.

End of Aisle Protectors

End of aisle guards protect the last frame in a row from forklift damage. These are typically high-traffic areas with fast-moving forklifts so these last frames are much more susceptible to damage.

Row End Protector

Row end protectors are used on rack systems with high-traffic aisles. The row end protectors are placed on the end of aisle frames at specific heights, offering added protection for the uprights from pallet and forklift damage.

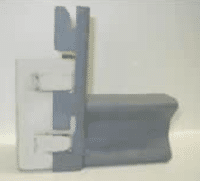

Safety Clips

Pallet rack safety clips create a safety connection between the upright frame and the cross beam so that beams cannot accidentally become disengaged. The most common style of pallet rack clip is the universal safety drop pin. Shop our online shelf clips store here.

Safety Netting

Safety Netting for pallet racking is typically made of nylon or plastic mesh. Pallet rack safety netting is secured to the back of the racking to prevent items from falling off the system.

Bollards

Warehouse bollards are solid vertical posts that often stand out in front of buildings, parking lots, or inside warehouses, to protect against vehicular damage.

Guardrail

Warehouse guardrail is a heavy-duty barrier that protects people, products, and warehouse facilities from bumps and falls.

Pallet Rack Backing

Rack backing is wire mesh rack guard paneling that attaches to the back of a pallet rack system and prevents objects from falling off the racking.

Wire Partitions

Wire mesh partitions are mesh panels or fully-enclosed safety cages that protect products and personnel. Such enclosures are now required for aerosol storage facilities.

Handrail

Warehouse handrails are a pedestrian safety product that helps safely guide people through walkways and up and down stairs, and on anywhere that balance or falling is a concern.

Engineered Pallet Rack Systems

Selective Pallet Rack

Standard Selective Pallet Rack is the most common warehouse rack style with the most flexibility. Selective systems offer easy pallet access by storing pallets in a single-deep lane. This way, pallets don’t obstruct one another and are always in the pick face. Most manufacturers make selective racking of their own. The main distinguishing piece between manufacturers and all selective rack styles is the beam-to-frame connection – the punch hole design on the uprights is the best indicator. Of these, teardrop racking has become the most common style.

Selective racking comes in both roll-formed and structural styles to meet the demands of specific applications. The structural design is commonly found in heavy-duty, rugged applications.

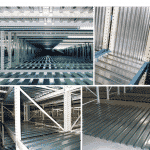

Drive-In Pallet Rack

Drive-in pallet racking boasts the greatest storage density of any of our engineered pallet rack systems. By eliminating the aisles in a rack system, the drive-in design is able to maximize vertical and horizontal space. In fact, drive-in pallet storage systems can increase storage by as much as 60%. drive-in, racking is also known as drive-through racking, with the only difference being that drive-through rack is designed to have lifts drive through the storage system, unlike drive-in, where the racks are up against a wall and the forklifts are not able to drive through the system.

Pushback Pallet Rack

Pushback rack allows you to maximize space without sacrificing smooth and consistent product rotation. Pushback pallet rack increases pallet count while simultaneously offering more pick faces than the traditional drive-in pallet rack system. These systems are also highly conducive to storing SKUs with multiple pallets and can store up to pallets six deep. Using carts to control the flow of each pallet, pushback maintains the LIFO product flow by placing pallets in front of the latest load and using gravity and the carts for control.

Pallet/Gravity Flow Rack

Pallet flow racking uses metal rollers and the force of gravity to feed pallets into the rack’s pick position and can get warehouses flowing. Like drive-in racking and other engineered systems, pallet flow eliminates aisles to maximize space by storing pallets in lanes. Gravity flow rack systems are engineered based on individual needs and are custom to the specific application.

Carton Flow Rack

Carton flow rack, also known as span track, work in coronation with pallet rack systems to offer a pick solution to accommodate high volume order picking operations. With reduced operator activity, carton flow systems use gravity and rollers to flow product forward to the pick position of the rack system. These rack systems are typically found in flowing warehouses with a large number of products being picked daily.

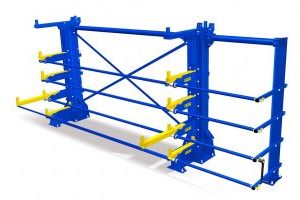

Cantilever Rack

Cantilever Racking is a free-standing rack system with arms that extend out from a single upright rather than beams. Cantilever systems are perfect for storing long, odd-shaped objects like pipes, metal sheets, lumber, carpet, furniture, and more. Inclined arms keep rolling products from falling off the ends.

Specialty Racks

Roll Out Rack

Vertical Sheet Rack

Stack Racks

Industrial Systems

Steel Shelving

Steel shelving is a smaller storage solution than pallet racking for light-duty applications. Shelving is typically hand-stacked and a wonderful option for garage storage or case storage. There are a couple different styles of shelving: rivet shelving, and industrial steel shelving are the most common.

Rivet Shelving

Rivet shelving rarely requires hardware during assembly. The beams are equipped with pre-manufactured rivets welded onto the end connectors. These rivets lock into place on the uprights, securely fastening the beam to the upright. This shelving style is often installed in bulk for case picking warehouses. Rivet shelving is less customizable than industrial steel shelving.

Industrial Steel Shelving

Industrial steel shelving is a highly customizable heavy-duty shelving option with many different add-ons like modular drawers, cabinets, dividers, and more. A steel shelving unit can be configured in many ways to best meet the needs of the storage user.

Shelving Accessories

Steel shelving can be customized and organized in many ways. Here are some of the most common steel shelving accessories and add-ons:

- Modular drawers

- Cabinets

- Cabinet doors

- Panel kits

- Locking doors

- Work benches

- Shelf dividers

- Storage bins

- Bin dividers

- Mezzanine components

Cleanrooms

Negative and positive pressure cleanrooms are common in the medical industry but go beyond that as well. These cleanrooms filter air in and out to manage airborne pollutants and keep things sanitary in an emergency or medical environment.

Security Cages

Security cages are wire mesh enclosures that protect product and personnel from machines, theft, and falling or flying objects. They help with controlled guest access at entrances and exits and are often required for aerosol storage.

Mezzanines

Mezzanines and work platforms are elevated platforms that add to the usable floor space in a warehouse. These platforms can be installed as free standing units or incorporated into a rack system to increase storage and picking space.

Modular Offices

Modular offices are pop-up office spaces that can be easily installed anywhere. They bring usable office or other space into the warehouse.

Medical Testing Booths

Medical testing booths like temperature screening and covid testing stations came into high demand during the coronavirus pandemic. We offer medical testing booths and can help you choose the best fit for your facility.

Automated Systems

VRC & Lifts

VRC lifts and other freight lifts carry freight and personnel from one level to another such as a mezzanine in a warehouse. These hydraulic or electric lifts optimize warehouse flow and decrease risk of injury from carrying products up and down stairs.

Shuttle Systems

Pallet shuttle systems are generally used for high-density deep lane storage. They allow companies to store pallets deep within the system without having to manually enter the system with a forklift that can easily damage the rack.

Automated Storage & Retrieval Systems (ASRS)

Automated Storage and Retrieval Systems (ASRS) store and retrieve pallets on demand. These systems allow businesses to utilize the full height of their warehouse and achieve high-density storage.

Carousels

Carousels rotate products horizontally or vertically to the pick face for easy access. They are typically used for parts storage and minimize walking distance for warehouse employees.

Warehouse Robotics

AI technology and robotics are popping up in more and more warehouses around the globe. These amazing technologies are optimizing workflow and opening up greater opportunities for employees within the warehouse.

Our Services

Warehouse Layout Design

AK offers extensive warehouse layout and design services. Our design experts are educated in warehouse codes, racking, and requirements. Let us partner with you in your warehouse design project!

Design Group

Our design group is a team of incredibly talented warehouse design experts who are excited to take your storage space from phase one to the end. We walk alongside you from inspection and design to installation. Contact us to get in touch with a design specialist today!

Project Management

Our project management team coordinates permits, installation, general contractors, shipping, and more. Without them, our business would not be able to run smoothly or efficiently.

Rack Buyback

We buy used pallet racking! If you need to sell your used racking, contact AK today. We will happily coordinate teardown and shipping as well as pay you for your used system.

Warehouse Space Planning

Our design experts can help plan your warehouse space and provide detailed CAD drawings. We can account for office space, industrial and automated systems, and storage rack.

Warehouse Relocation

Moving warehouses? AK can help! We are more than able to assist in your move and keep business running smoothly throughout the process. We typically move product in phases to account for new and old pallet rack installation and teardown. We will even buy your old racking from you and take it off site for free.

Permitting

We are experts in warehouse permitting. Although permit requirements vary from city to city, we can answer any questions and point you to the right resources regarding permitting and safety standards.

Rack Inspection

Pallet rack inspections are a necessary safety measure. Stay out of trouble from regulatory agencies like OSHA by performing regular rack and warehouse inspections. AK will happily send a team member out to inspect your racking for damage or missing components if possible.

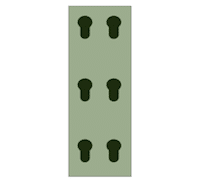

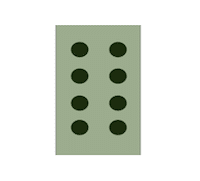

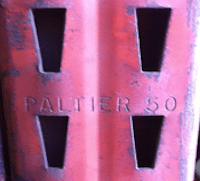

Pallet Rack Identifier

Our pallet rack identifier helps customers identify their mystery racking. When pallet racking is missing labels or branding, the upright punch hole design is the second-best way to determine the rack brand and style. Use this online tool to compare punch hole designs and identify your racking!

ARTCO

Tube Rack

ARTCO

Structural

BULLDOG

Keystone

BULLDOG

Ridgid Slot

BULLDOG

Teardrop

BURTMAN

HUSKY

Crashguard 2000

EMI RACK

EXCEL STORAGE PRODUCTS

Teardrop

FRICK GALLAGHER

HANNIBAL INDUSTRIES

Tube Rack

HILINE

HUSKY LYNX RACK

Slotted

HUSKY RELIABLE RACK

Keystone

INTERLAKE

New Style

INTERLAKE

Teardrop

INTERLAKE

Old Style Teardrop

LYON

Teardrop

M-I-RACK

MASTER RACK

Buckley

MECALUX

Teardrop

PALMERSHILE

PALTIER 50

Old Style

PALTIER

PENCO CLIPPER

PREST LOCK 1

PREST LOCK 2

REDIRACK

Konstant

REPUBLIC

Keystone

RIDG-U-RAK

Paltier

RIDG-U-RAK

Slotted

RIDG-U-RAK

Teardrop

SAMMONS

PREST

Slide N Lock

SPACERAK

New Style Teardrop

SPACERAK

Old Style Teardrop

SPEEDRACK

SPEEDRACK

Teardrop

STEEL KING 2000

Boltless

STEEL KING 2500

Bolted

STRUCTURAL

UNARCO

Sturdi-Bilt

UNARCO

T-Bolt

TRIBORO

Teardrop

TRIPLE A

UNARCO

Teardrop

UNARCO II

UNIRACK

Teardrop

UNITED STEEL PRODUCTS

Teardrop

WC CARDINAL

Teardrop

BUCKLEY

TEARDROP

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.