Standard Pallet Rack Systems

Standard pallet rack, also know as “selective pallet rack” is the most common pallet storage racking found in warehouses today. At AK Material Handling Systems, we’re committed to supplying our customers with the high quality, name-brand pallet rack they need. As part of this commitment, we carry a selection of new, in-stock selective teardrop pallet rack that is second-to-none. With two warehouses in strategic shipping locations (Maple Grove, MN and East Stroudsburg, PA), we’re able to offer our customers a large freight advantage. Our inventory features a number of the most trusted manufacturers in the industry: Ridg-U-Rak, Speedrack Products Group, Steel King, SpaceRak, and Interlake. We compliment our pallet rack inventory with a massive amount of pallet rack wire decking in stock as well. We stock J&L Wire and ITC Wire mesh products for our racking systems. For AK Material Handling Systems, no project is too big or too small to handle. Customers with larger warehouse projects can receive factory direct discounts, as well as warehouse layout and design consultation. Read More about Standard Pallet Rack Systems

Push Back Pallet Rack Systems

When space in your warehouse is tight, pushback pallet rack is king. Pushback pallet rack systems increase storage density, allowing you to truly make the most of your available warehouse space. These systems offer the ability to increase pallet count without sacrificing selectivity. This feature gives pushback systems a leg up on many traditional storage systems, and the superior combination of density and selectivity means you’re getting the most of out of your warehouse in terms of efficiency. AKMHS partners with multiple manufacturers and vendors to find the exact pushback system for your warehouse. With over 25 years in the industry, we have numerous warehouses in Minnesota and across the country that are currently using an AK pushback pallet storage system. Read More about Push Back Pallet Rack Systems

Drive In Pallet Rack Systems

Drive-in pallet rack systems boast the greatest storage density of any of our engineered pallet rack systems. By eliminating aisles, drive-in pallet rack systems are able to maximize warehouse storage space. In fact, a drive-in rack system can increase your pallet storage by as much as 60%. Due to their ability to deliver optimal storage density, drive-in rack systems are prevalent among warehouses with first-in, last-out inventory rotations. Drive-in racking is also commonly referred to as “drive-through high density storage.” Read More about Drive In Pallet Rack Systems

Pallet Flow Rack Systems

Gravity flow pallet rack systems, also known as pallet flow racks, can get your warehouse flowing. Pallet flow rack systems use metal rollers and the force of gravity to feed pallets into the rack’s pick positions. Like drive-in rack systems, gravity flow racking maximizes storage space by minimizing aisles. Unlike drive-in systems, however, gravity flow systems operate using a first-in, first-out sequence. Gravity pallet flowing systems are engineered based on individual needs, and can be designed to hold up to 20 pallets deep in a single lane of storage. AK’s pallet flow designs are engineered to perform and manufactured to last! With pallet flow rack systems, we provide custom solutions for all applications, from economical shallow depth pick module systems to the most challenging deep lane flow systems in harsh environments. Read More about Pallet Flow Rack Systems

Carton Flow Rack Systems

Carton flow storage systems, also called span track, are designed to accommodate high volume order picking and allow reduced operator activity. Similar to gravity flow pallet systems, carton flow systems use gravity, as well as metal or plastic rollers to “flow” inventory stored in cartons or boxes. They are commonly found in “flowing” warehouses that have a high volume of products being picked daily. Because these systems are gravity-driven, they work excellently with conveyor picking as well, providing both maximum visibility and order accuracy. Carton flow will help you increase productivity on the line, create a safer warehouse and maximize space. Read More about Carton Flow Rack Systems

Cantilever Rack Systems

Some materials don’t fit neatly or effectively into pallet rack systems. Lumber and steel, for example, are often too long and awkward to fit on pallets, and may not have squared edges. Materials such as these are best stored using cantilever rack systems. Cantilever warehouse storage rack systems are ideal for storing long items in continuous horizontal runs, which keeps vertical uprights from interfering with the placement of the product on the shelf. Cantilever racks can be found in a wide variety of settings, such as lumber yards, hardware stores, or plumbing supplies warehouses. As with selective pallet rack, we have cantilever rack in stock at our Maple Grove, MN location. Read More about Cantilever Rack Systems

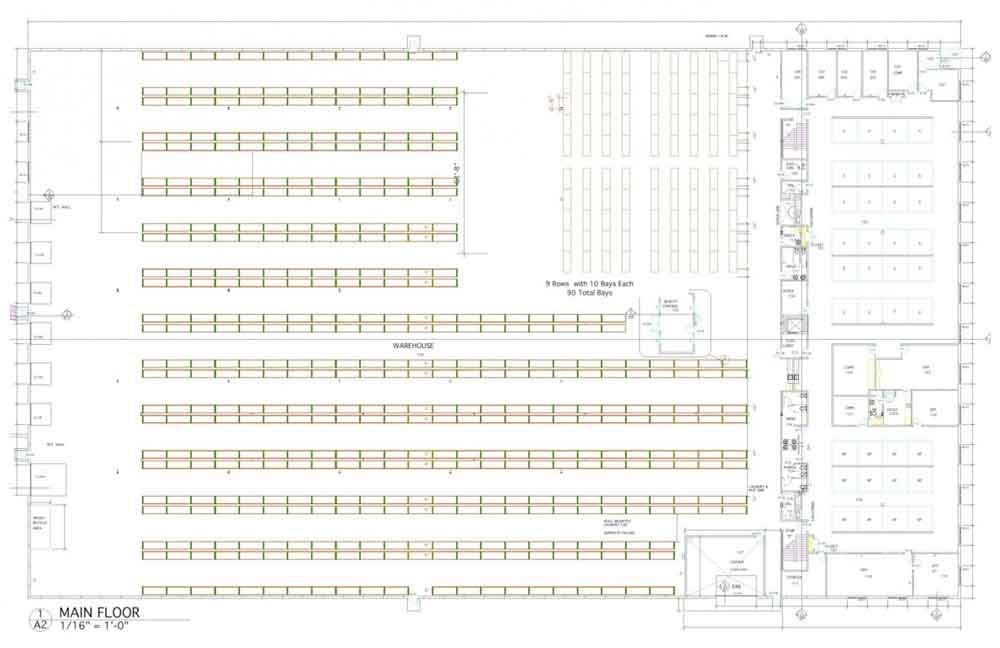

Warehouse Layout & Design

In addition to supplying customers with top-tier pallet rack products and engineered rack systems, AK Material Handling Systems provides warehouse design services for the storage and handling of materials through manufacturing, warehousing and distribution centers. AK Material Handling Systems’ professional designers have acquired years of experience listening to the needs of customers, and will work to provide you with the customized system that’s right for you. We also work closely with industrial real estate professionals, helping their clients find the right industrial space for their business. We offer free budgetary numbers, along with rack layouts to help our customers make the right choices when searching for a new warehouse location. Read More about Warehouse Layout & Design

Industrial Racking for Sale

Industrial racking for sale! Without industrial racking, you can only stock items as high as you can reach. When things get tight on the ground, most buildings still have plenty of unused vertical space. All you have to do is look upward to see that most of the available space in a building is higher than we can reach. Warehouse pallet racking systems allow you to tap into your unused vertical space, making your storage more efficient. Connect with us to learn which industrial racking would optimize your current location’s space. Customers often come to us with plans to buy or rent additional storage space when all they need to do is make better use of their current place. Our job is to help them do that. Read more about Industrial Racking for Sale

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.