What are Warehouse Robotics and AI?

Warehouse robotics are the future of warehousing and fulfillment centers. Artificial intelligence is being implemented in more and more warehouse operations around the globe. Warehouse automation optimizes the picking and packing processes, increasing order fulfillment and profits.

Not all warehouse robots have artificial intelligence – some simple applications don’t require AI to succeed. However, AI is a game changer for many businesses, opening new doors and ways of storing and handling products.

Automated Warehouse Robots

Automated warehouse robots are great at performing repetitive tasks in a production line, like packing and palletizing. There are many kinds of warehouse robots, each customized to the application and task.

Robot customization occurs during an extensive testing period within the unique application. Practice with the exact product and packaging system is essential to ensure smooth processes once implemented in the storage facility.

Artificial Intelligence

Pre-developed AI algorithms allow robotic workcells to perform human skills like recognition, grasping, and decision-making.

Here are some of the tasks robots can now perform in the warehouse through advancing AI technology:

- Object recognition

- Pose determination

- Grasp points computation

- Decision making

These skills come into play for end-of-line processing, packing, and food handling. RIOS develops superior end-of-arm tools that allow robots to grasp and move delicate items like food. Their AI vision system inspects products and monitors quality control.

Our Warehouse Robotics Manufacturers

AK Material Handling Systems partners with RIOS Intelligent Machines to provide storage facilities with high-quality warehouse robotics and artificial intelligence.

About RIOS Intelligent Machines

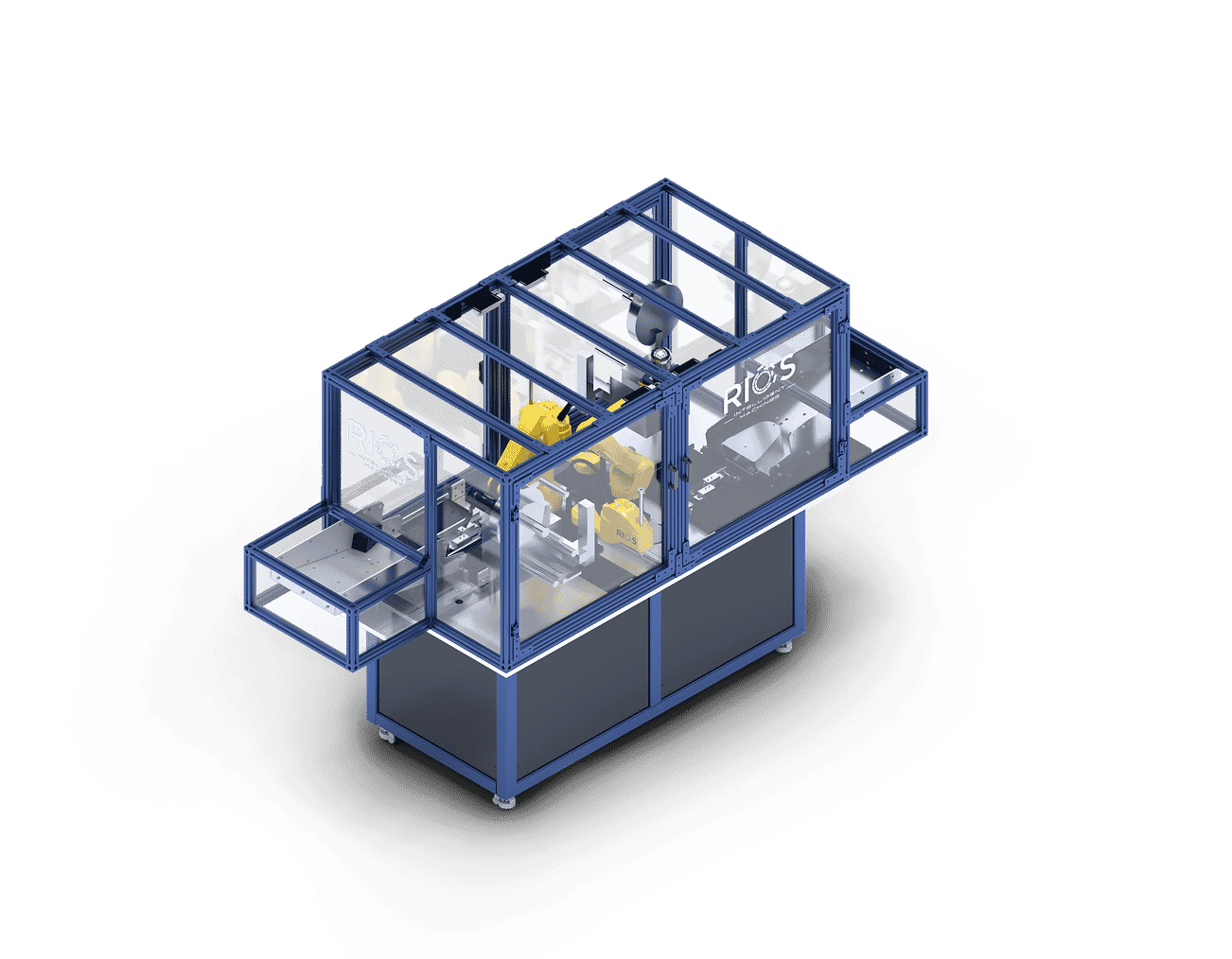

RIOS is a lead manufacturer of warehouse robotics based out of California. They manufacture a variety of robotic workcells and are leading the charge in Robots-as-a-Service (RaaS).

RIOS robotic workcells are “bringing the manufacturing sector into the 21st century”. Together, we can’t wait to help your business get there too.

Find more on RIOS robotic solutions and workcells below.

Warehouse Robotics Solutions

Machine Tending

ASTRIA is RIOS’ machine tending and material handling robot. Equipped with an AI-powered vision system, this workcell quickly inspects and identifies new objects. This system handles incoming and outgoing products by:

- Managing a continuous flow of products

- Adapting to new SKUs without additional programming

- Integrating with existing line equipment

- Working with any size application

- Performing product counting

Food Handling

DION handles food, even soft food items, with ease and dexterity. It is another AI-powered workcell with food-grade grippers and advanced sensors. The DION robotic workcell:

- Is compatible with food grade and wash-down environments

- Manages a continuous flow of goods

- Integrates with baking, oven, cooling, and other food-handling racks

- Handles pan and tray loading and unloading

Quality Control

LUMOS is an AI-powered quality control machine designed to optimize product shipping and minimize quality issues. This robot inspects products on a compact platform or conveyor system before shipping.

- Seamlessly integrates into any point of the production line

- Adaptable to many product shapes and sizes

- Processes 100 items per minute

- Suitable with many applications, including food grade

Packing & Palletizing

Pack out to boxes

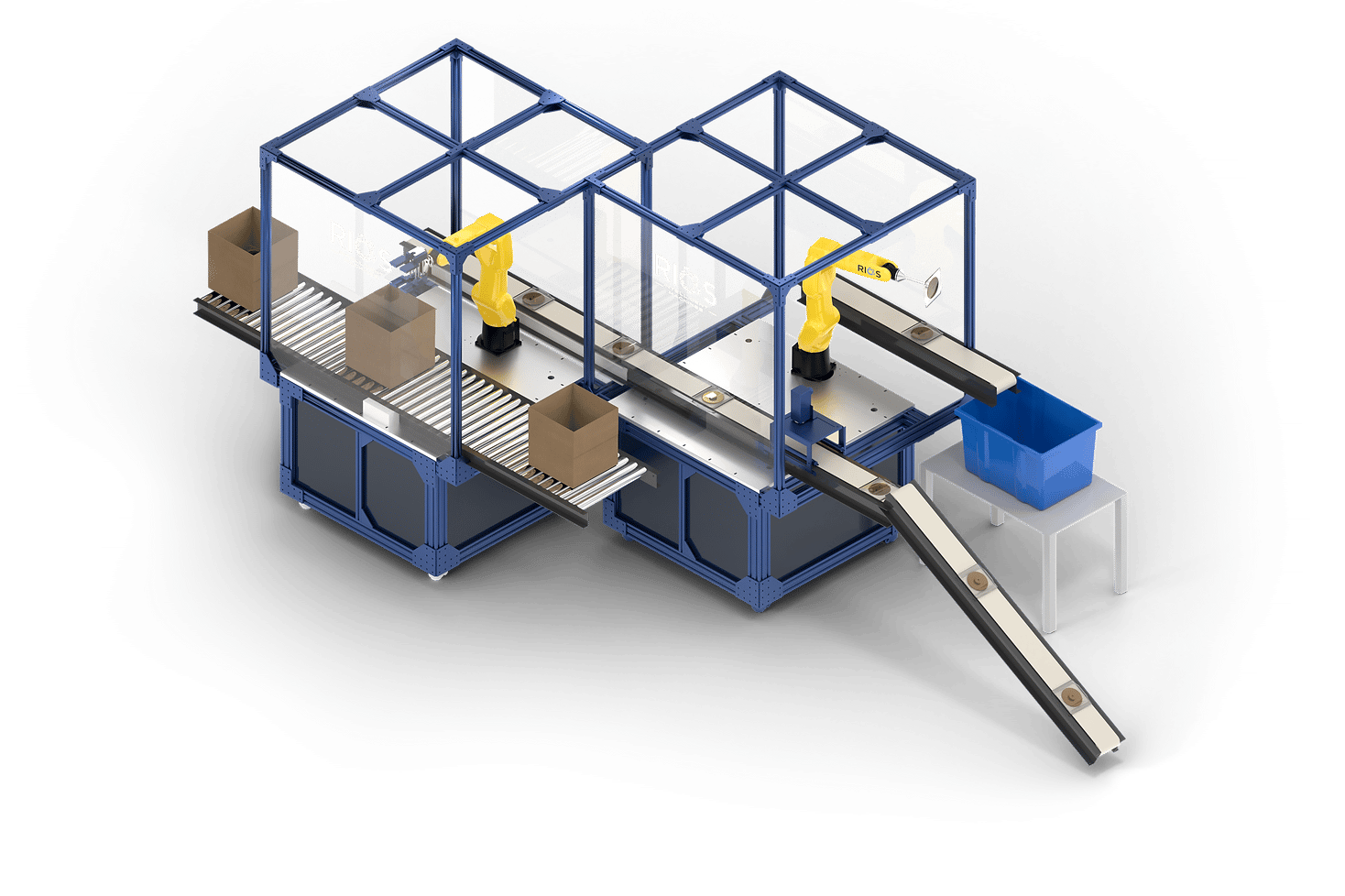

VULCAN is an end-of-line packaging machine specializing in packing various products into boxes and palletizing.

- Manages a continuous flow of boxes

- Handles dozens of items each minute

- Accommodates different box sizes

- Able to lift a wide variety of products

Pack out to polybags

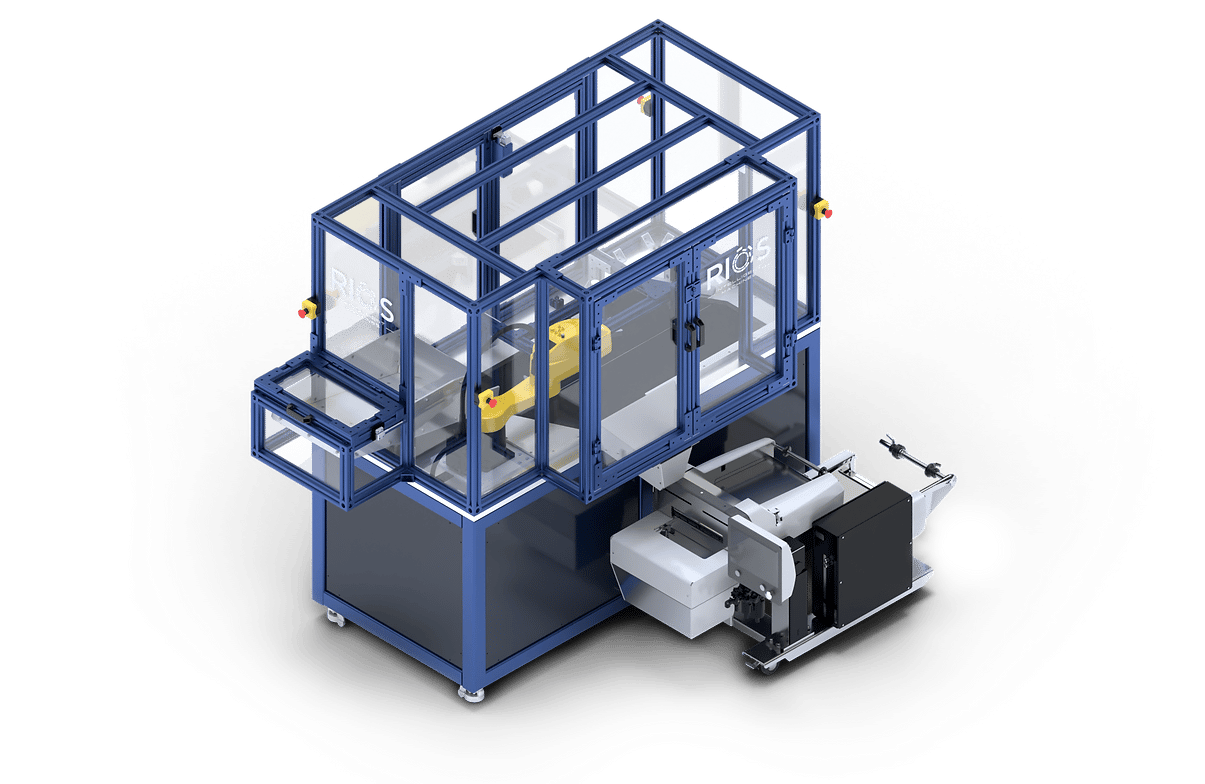

HERMES is a packing robot designed to pack a wide range of SKUs into polybags. AI-powered vision technology allows this machine to track objects at microseconds speed. The system’s robotic arms pack at twice the speed of human operators.

- Handles 40-60 items/minute

- Adaptable to products of various sizes and weights

- Manages a continuous flow of goods

- Unloads a variety of equipment or conveyor systems

How Much Do Warehouse Robots Cost?

RIOS offers a unique system rental program. This system protects companies from expensive maintenance and repair costs. By renting a RIOS workcell, customers avoid any up front purchase with the benefit of unlimited repairs and support.

Each application is unique, and the cost varies accordingly – an average hourly price is $25 to $30 an hour. This price can increase to $55 to $60 an hour, depending on the workcell and equipment.

The best way to calculate the cost is in savings. RIOS robots operate up to 1.5x faster than any human operator, reducing labor costs while increasing productivity. System accuracy is within 0.1″, reducing human error and hiccups in production and packing flow.

Finally, companies save money from increased efficiency. RIOS robotics pack and handle up to 60 items per minute, nearly doubling the output of any human operator.

Maintenance and Upkeep

RIOS’ robotics rental system saves a lot on maintenance and repairs. Renting keeps customers in close contact with the manufacturer during use. This way, if the work cell malfunctions, the company has continuous support and unlimited repairs. RIOS is always on call and ready to jump into action.

RIOS and AK provide turnkey robotics services, including installation, acceptance testing, preventative maintenance, and ongoing support. We are only a call away if you ever have questions about your system or need maintenance support.

This unique rental approach is much more economical and environmentally and keeps robots from the junkyard in case of malfunction.

Robotics Warehouse Consultation

To discuss robotics solutions for your warehouse, call AK at 800-722-5908. Reach out to schedule a warehouse visit and consultation to see if robotics may be a good fit for your application.

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908