Are you a business owner in need of warehouse space planning? We offer professional warehouse space planning services and can help you map out your storage space.

Never try to tackle the task of moving or expanding your warehouse alone. Sure, solo warehouse space planning might be possible in some cases, but there’s a good chance you’ll be risking the safety of your product and employees by not having a design professional involved. Get professional warehouse layout and design help today!

Below, we outline the ten best reasons to have a professional design your warehouse, and the 5 “P”s of warehouse space planning.

Warehouse Space Planning

At AK Material Handling Systems, we:

Work with you to figure out how much industrial and office space you’ll need before you start looking. If you can’t accurately calculate how much space you need, searching for a new location is an exercise in futility.

Live and breathe pallet rack. We are experts in cantilever, drive-in, pushback, pallet flow, selective pallet racking, and more. We can help you determine which style is right for your operations. As we always say, no rack system is right for everyone. We’ll use our experience and product knowledge to advise you on the type of rack system that will result in your optimal warehouse storage solution.

Don’t just do rack, but work platforms and modular offices as well. Have you considered a modular office or work platform? Much of the time, it’s a better idea to make full use of the warehouse space you have before looking elsewhere. We can engineer work platforms and install modular offices that make use of your available warehouse space and mesh with your current operations.

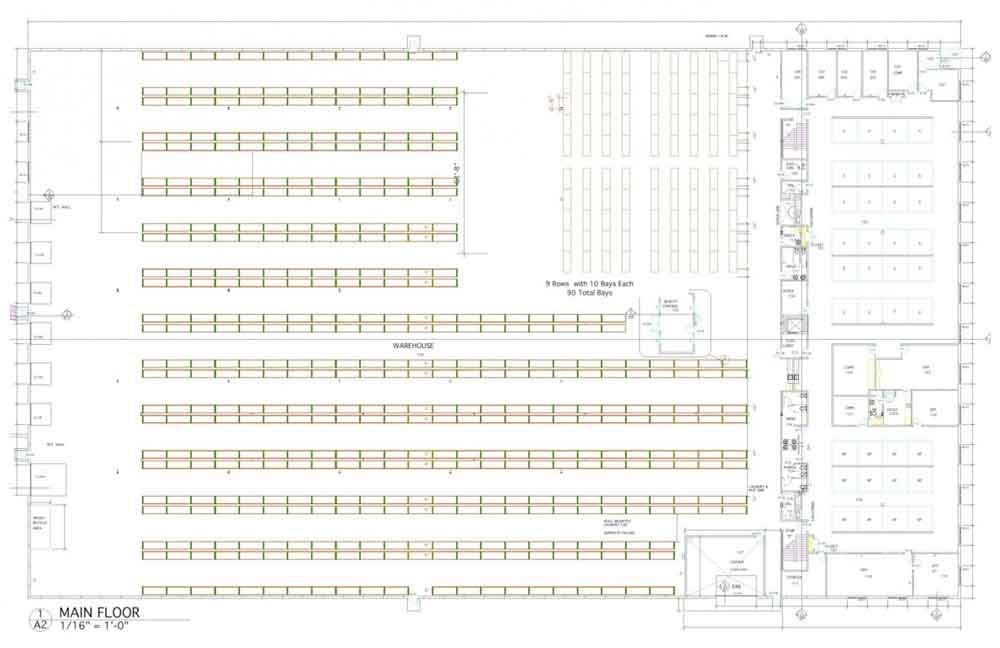

Provide detailed CAD drawings for your warehouse, each of which provides a unique warehouse layout and design option. If you do not have the ability to create your own CAD drawings, you will need to contact a professional with the ability to do so. This is an essential part of warehouse space planning, and our systems design specialists have years of experience.

Provide high-density storage rack systems, allowing you to make the most of your current warehouse space. The more product you can store in a given warehouse space, the greater the density. We specialize in maximizing your warehouse storage density to make your money go further.

Give you our unbiased opinions and recommendations regarding your current warehouse operations and warehouse space plan. Our customers deserve honest opinions about their storage racks, forklifts, and what’s in their best interest.

Give you our professional advice on your industrial real estate options. A helpful, professional opinion is nice in any large decision-making moment which is why we advise our customers on their warehouse space planning.

Keep over $1 million in pallet rack products in stock and can install systems in your warehouse in just days. Most people don’t want to wait months to get anything, let alone a product as important as pallet racking. Sometimes it’s unavoidable, but those times are much less frequent when you have over $1 million worth of new and used pallet racking on hand.

Are well-versed in building codes and warehouse safety standards. There is perhaps no greater nightmare scenario than building a rack system and having to tear it down later because it doesn’t meet the state and local codes. Don’t let it happen – we know pallet rack permitting, and we’ll design your system to meet regulations.

Can give you trade-in value on your existing racking materials. If you’ve got a pallet rack system you want to replace, we’ll tear it down for you and deduct its value from the cost of your new system. All around, this rack buyback program is a pretty good deal.

The 5 P’s of Warehouse Space Planning

You’ve probably heard the saying, “Proper Planning Prevents Poor Performance,” or some version of it. You may have even heard it so many times that you’d just as soon never hear it again. But even though the “5 Ps” might be cliche, it consistently pops up because it’s so often true – whether it be in terms of exams, public speaking, and, yes, even warehouse space planning.

One of the unfortunate and recurring trends we notice in the commercial real estate world is neglecting space planning and a failure to recognize the importance of laying out warehouse operations in the early stages of the buying or relocation process. Instead of assessing the business’s current and future storage needs at the outset of the project, many companies and real estate firms find industrial space first, then try to tailor the business’s processes to fit the building’s dimensions and layout restrictions. While this may not mean the end of the world for these organizations, failure to do proper space planning can result in a long list of avoidable storage issues.

So how can we avoid less-than-optimal layouts and apply the 5 Ps to warehouse space planning? Here are some do’s and don’ts that are useful rules of thumb to keep in mind when planning warehouse space to get started in the right direction.

What To Do When Planning Warehouse Space

- Have a warehouse layout and design professional assess current warehouse operations and determine the ideal layout.

- Enlist an expert’s help to do a walk-through of a space and provide CAD drawings to visualize what an optimized warehouse storage solution would look like.

- Ask questions. For example: “Is this X sq ft area large enough for my operations?” “How much storage will I gain by going to 32′ clear?”

- Take advantage of the complimentary professional warehouse layout and design services available to you.

- Stay on top of current building codes and standards, or work closely with someone who is.

- Get advice on industrial real estate options.

Warehouse Space Planning Don’ts

When planning your warehouse space, don’t:

- Wait until the last minute to think about warehouse storage systems.

- Transfer new racking and other warehouse equipment into the same layout in a new building because “it’s always been done that way.”

- Experience losses in productivity, capacity issues, or storage shortages because of a failure to plan for growth and inventory fluctuations.

- Wait too long! Lead times for large projects can be as long as 12 or more weeks, leaving considerable downtime without proper planning.

These aren’t exhaustive guidelines for a warehouse move, but hopefully, each can serve as a helpful reminder. As you might have gathered, warehouse space planning is a matter of timing, asking the right questions, and working with an expert in the field of warehouse layout and design. Like almost any business aspect, a little planning and preparation can go a long way toward helping you achieve your goals.

Contact A Warehouse Space Planning Expert

For help planning your warehouse space, contact our warehouse design experts! Call 800-722-5908 or fill out a quote form for professional assistance today.

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.