What are Warehouse Conveyor Systems?

Warehouse conveyor systems, or pallet conveyors, are transportation devices that move pallets throughout a warehouse facility on rollers or conveyor belts. Conveyor systems can be operated manually, by gravity, or automatically with a motor system.

Automated warehouse conveyor systems are powered by a motor and move pallets independently of manual assistance. There are motorized roller conveyors as well as automated conveyor belt systems.

The implementation of warehouse conveyors is a massive leap for warehouse automation — conveyors quicken material handling processes and order fulfillment, allowing warehouses to be more productive and efficient. Please keep reading to learn about different conveyor systems and their effect on material handling.

Types of Warehouse Conveyor Systems

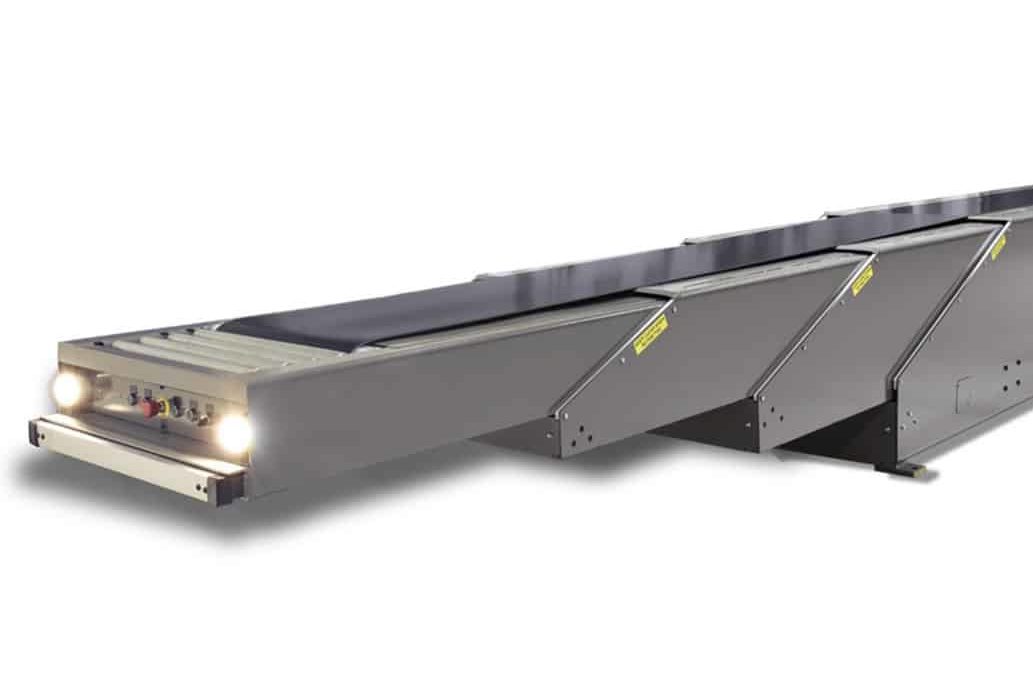

Extendable Conveyors

Extendable conveyors are telescopic conveyor systems that simplify loading and unloading trucks. These systems extend directly into a truck or trailer, reducing unnecessary walking and labor requirements in a distribution center.

Roller Conveyors

Gravity and powered roller conveyors are the two main types of pallet roller conveyors. Both types use plastic or metal rollers to move products either automatically or with the help of gravity over a slight incline.

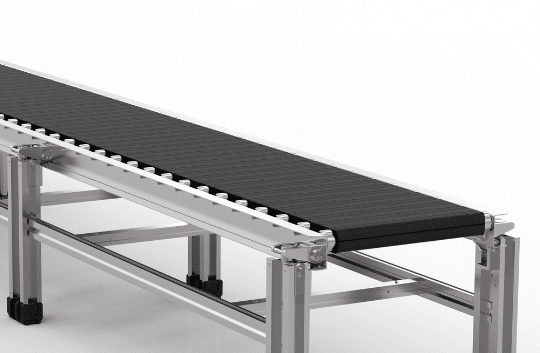

Belt Conveyors

Belt conveyors are the most versatile conveyor option, consisting of a single belt and pulleys that drive an endless, moving loop. Belt conveyors are ideal for products of varying shapes and sizes. Here are some of the most common types of warehouse belt conveyors:

- Modular belt conveyors

- Cleated belt conveyors

- Curved belt conveyors

- Incline/decline belt conveyors

- Flat belt conveyors

- Slider bed conveyors

Inclined Conveyors

Inclined conveyors typically use gravity to pull products down the conveyor lane. Both roller and belt conveyors can be installed at an incline to move products up or down from various warehouse levels.

Accumulating Pallet Conveyors

Accumulating pallet conveyors allow products to gather in one place for picking and packing. They include a temporary buffer zone where products can accumulate before continuing their journey down the conveyor. Zero-pressure accumulation conveyors have a braking system that controls the conveyor’s speed, protecting fragile packages.

Chute Conveyors

Chute conveyors are one of the simplest and least expensive gravity conveyor options. These conveyors help accumulate products in shipping areas. Spiral chutes are vertical conveyors that transfer products from high storage levels like mezzanines. These conveyors save valuable warehouse floor space.

Sanitary and Washdown Conveyors

Sanitary conveyors are ideal for food production and other sanitary applications. Plastic or metal mesh belting allows for simple cleaning and washdowns even while the system is in use. These conveyors can withstand fast and rigorous sanitation processes.

Specialty Conveyor Belts

There are numerous specialty conveyor belt options suitable for different applications and environments. The belt material governs how well a conveyor belt will withstand unique strains like extreme temperatures, x-ray applications, and messy food handling. Contact AK to learn more about conveyor customizations for your project.

Our Warehouse Conveyor System Manufacturers

Ermanco

Rapistan

How Much Does a Conveyor Belt Cost?

Conveyor belt cost varies significantly by system size and type. Conveyor belt size includes length, width, and drive pulley size. The conveyor type, material, and incline also affect the overall price.

You can expect to pay anywhere between $10,000 and $400,000 for a warehouse conveyor system. A decent estimate for the installation cost including all components, accessories, and hardware is $1,500 per linear foot of conveyor. Because cost varies so much, you will need to reach out to AK or your conveyor manufacturer for a specific quote for your project. Don’t hesitate to fill out a quote form or call us today!

Need Help Finding a Warehouse Conveyor System?

Our warehouse design team specializes in pallet conveyor system design — call 800-722-5908 for help finding the best length and type of conveyor solution for your warehouse operations.

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.