The Design Group: A White Glove Service

When skill, experience, professionalism, and customer service come together, you get the AK Design Group experience. From the first phone call to the final project walk-through, personalized service and attention to detail are our M.O. Whether you’re in need of a small rack system and some sound advice or complete turnkey services for a large-scale warehouse project, the Design Group’s job is to use a client-focused approach to deliver a storage system that maximizes your space. Read more about the Design Group

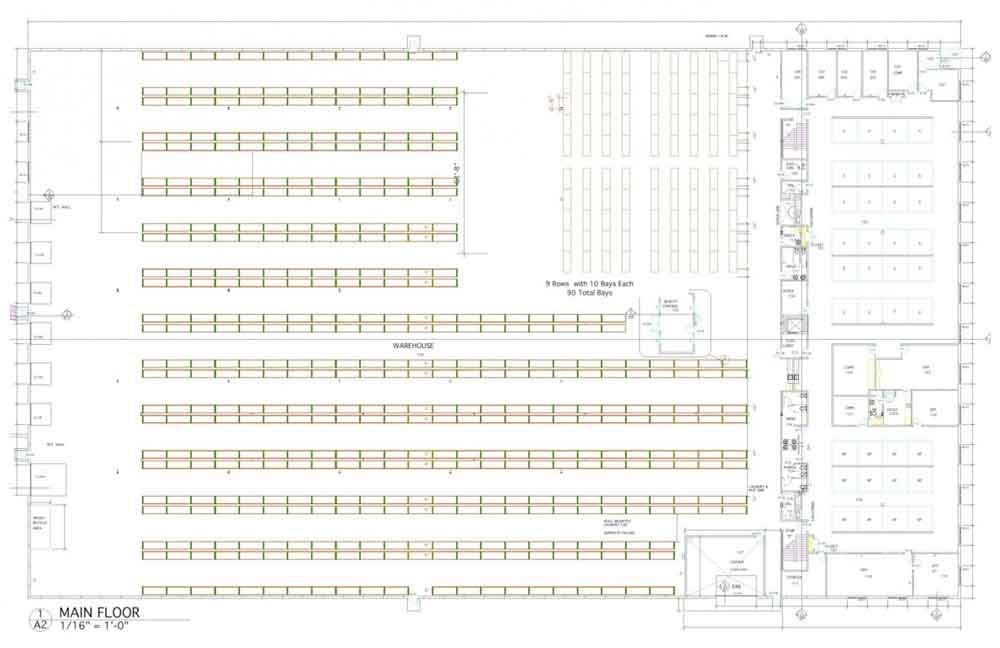

Warehouse Layout Design

We are a warehouse design company. Proper and professional Warehouse Layout Design is essential to the success of your business when moving into a new facility or distribution center. No matter the space, if your warehouse is not optimized or laid out correctly, you’ll probably incur losses in productivity, experience space capacity issues, and be forced to deal with storage inadequacies. Not only will our rack systems design specialists help you avoid these common pitfalls, but they’ll also elevate your warehouse and material handling processes to peak efficiency and production. Read more about Warehouse Layout Design

Warehouse Space Planning

Do you have any do-it-yourself projects lined up? DIY projects are great – in fact, a lot of us here at AK are full on DIY-ers, especially when the weekend rolls around. We just hope that none of your do-it-yourself projects include trying to tackle the task of moving or expanding your warehouse. Sure, it might be possible to do it in some cases, but there’s a good chance you’ll be risking safety and/or lack of efficiency by not having the pros help you out with it. Why, exactly, is this the case? Because we know you don’t have time to read a novel or a manual about it, we’ve outlined 10 of the most important reasons. This way, you can jot them down or use the list for future reference. Read more about Warehouse Space Planning

Project Management

Warehouse projects can range from from a few sections of rack to tens of thousands of pallet positions. In either case, we have learned how important our project management team is. Coordinating permits, customer, installation, teams, general contractors, and trucking can be very time consuming. When done right, everyone is happy. Communication is the key. Customers love hearing about the schedule without having to ask. When they do ask a question or need to make an adjustment, they have a team they know they can reach on short notice. Our project management team has proven itself to eliminate headaches and unnecessary costs. Read more about Project Management

Warehouse Relocation

If your existing racking works with your new layout and facility we can work with you to tear it down and reassemble it in your new building. Often times this is more cost-effective to you and doesn’t disrupt your business too much during the transition phase.

You may prefer to have us set up new racking in the new facility prior to relocating.

This way we can move all your product over in a seamless move.

We then come back and tear down your old racking and give you the option of selling it to us. Read more about Warehouse Relocation

Permitting

In general, most warehousing projects now require some sort of permitting or documentation. There are two parts to the typical pallet rack permit. First, there is the High Pile Permit. The documentation needed is normally provided by your architect. They take the rack layout and provide a design showing that egress aisles, emergency lighting, and the fire suppression system is adequate for the products and type of rack being used.

The other half of the permit process is the structural portion. Usually, a P.E. will evaluate the rack design, review the slab specifications of the building, and seismic conditions. A stamped copy will be submitted with the permit application.

In some cities, they will run the High Pile and Structural permit together. Others will not accept the general rack permit application without first getting the High Pile permit. Below we will give you insight on what you need to do to secure proper permitting. Read more about Permitting

Rack Buyback

We offer you the option of purchasing your racking that we’ve torn down either for a relocation project or simply because you are downsizing and no longer need the racking.

AK’s purchasing team gets counts and sizes of racking and provides a purchase offer. Once agreed on the offer, we provide a purchase order for your racking and cut them a check.

This method is how we receive the purchased racking into our inventory. Read more about Rack Buyback

Rack Inspection

Per RMI guidelines for Rack Repair Inspection, thoroughly examine the following areas of the racking system: proper anchoring on the solid base plate, examination of all bracing, horizontals, and diagonals, ensure the welds are intact, no crimping or damage to the braces, inspect that the upright columns are plumb and straight, examine any impact damage to the upright column to ensure there isn’t any crease in the steel, examine beam connections to be sure they are intact, examine beams to be square to the column with no observable impact damage. Read more about Rack Inspection

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.