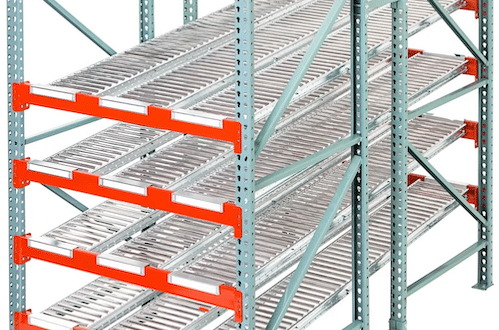

Carton flow rack (also known as flow rack, gravity flow, case flow racking, and more) is a first-in, first-out (FIFO) gravity-driven warehouse rack system for high-volume order picking. Like pallet flow rack, carton flow storage racking carries boxes, cartons, bins, or totes from the loading aisle to the picking aisle on rollers or wheels.

Carton flow lanes easily integrate into existing pallet rack structures and typically store hand-stack boxes or cartons for split case and piece-picking applications like candy, hardware, or small parts. Each carton flow system is custom-designed around the product and application and can significantly improve efficiency in case picking warehouses.

If you are interested in carton flow racking for your warehouse, contact one of our design specialists at 800-722-5908 or fill out an online quote form to get started!

How Carton Flow Rack Works

Carton flow rack systems are hand-picked FIFO storage systems that keep inventory fresh and ready to pick. These high-density storage systems utilize gravity to pull loaded boxes and cartons to the pick face on inclined wheel/roller beds. Separate aisles for loading and unloading allow simultaneous picking and restocking for high-efficiency order picking.

Carton flow wheel beds drop directly into existing pallet rack bays or can be installed as stand-alone units. Like-SKUs are stored within a single lane, and each pick face displays a different SKU. This high product visibility simplifies inventory management and stock control.

Carton Flow Rack Advantages

Accessible: Provides open access to every SKU stored within the system.

Enhanced Stock Rotation: First-in, first-out order picking prevents spoilage due to prolonged storage.

Space Utilization: High-density carton flow storage saves valuable warehouse floor space.

Efficient: Streamlines picking operations.

Visibility: Products are more organized and accessible, so it’s easier to track inventory levels.

Cost-Effective: Offers long-term savings on reduced labor costs, improved space utilization, and better inventory management and saves up to 75 percent of labor costs compared to static storage.

Safe: Less product damage occurs in carton flow systems.

Versatile: Carton flow lanes easily integrate within existing pallet rack structures.

Customizable: Custom-designed for each application and easy to re-slot or reconfigure.

- 3D Storage Systems

- Advance

- Engineered Products

- Interlake Mecalux

- Keneco

- Mallard Manufacturing

- Rack Builders Inc.

- UNARCO

- UNEX

Carton Flow Components

- Rack Structure – Carton flow integrates with new or existing pallet rack structures. When selecting your racking, consider the storage application for the proper rack size, style, and material. Common pallet rack types include galvanized, painted, stainless steel, roll-formed, or structural racking.

- Flow lanes – Flow lanes are inclined storage lanes that house the wheel beds or rollers. Flow lanes are available in various widths to accommodate loads of different shapes and sizes. Cartons are pulled down the flow lane from the loading zone to the pick-face via gravity.

- Roller/wheel bed – Carton flow utilizes rollers or metal or plastic wheel beds to flow cartons through the system. See the types of carton flow section below to learn more about the different types of wheels, rollers, and alternative carton flow styles.

- Entry guides – Carton flow entry guides (or entry flags) make it easy to load items into the lanes consistently. They often snap directly into the lane at the loading zone and provide a barrier to push cartons against before they flow down the lane.

- Lane dividers – Carton flow lane dividers ensure SKU separation and precise order picking. These accessories keep cartons in their unique lanes and help keep carton flow systems organized.

- Impact trays – Carton flow impact trays absorb the impact of incoming cartons at the pick face. These flat metal trays are installed horizontally at the end of the flow lane to evenly distribute heavy loads onto tracks and increase the longevity of a carton flow system.

- Tilt trays – Carton flow tilt trays are installed on the pick side of a carton flow system to increase visibility and improve order picking rates and efficiency. These metal trays tilt cartons outward toward the pick face and are ideal for “each” picking or piece-picking applications.

- Mounting brackets/hangers – Carton flow mounting brackets are essential hardware components that mount carton flow lanes to the pallet rack beams. These brackets can be placed at any beam level to control the lane’s pitch.

- Rear stops – Carton flow rear stops (or end stops) bolt onto the end of a carton flow lane to stop cartons in their tracks. End stops keep cartons securely in their lanes and prevent them from falling off the end of the flow lane.

Types of Carton Flow

Low Profile Carton Flow

Low-profile carton flow saves vertical space and is ideal for high-density storage applications. In low-profile systems, the roller profile sits below the pallet rack beams, allowing the front beam to act as a carton stop.

Keg Flow

Keg flow is a variation of carton flow designed for kegs, aerosols, and other cylindrical products. Metal barriers divide keg flow lanes and keep kegs separated and sitting upright within the system.

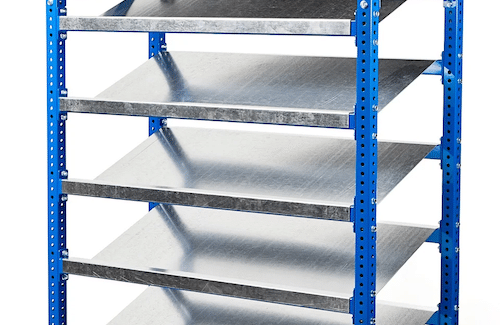

Tilted Shelving

Wire mesh and solid metal tilted shelves slope towards the pick face and utilize gravity. Tilted shelving increases visibility and accessibility for split case picking.

Unlike flat, static shelving, tilted shelves keep products at the pick face and allow for safe, ergonomic picking practices. Tilted shelves are much shallower than standard carton flow and are ideal for slow-moving SKUs.

Roller Lane Carton Flow

Roller lanes use full-width steel or aluminum rollers suspended between two channels. The independent axle design allows rollers to turn independently of each other.

Full-width rollers provide a large surface area to evenly disperse load weight. Roller lanes are ideal for operations with similar carton sizes that require dedicated carton flow lanes.

Wheel Bed Carton Flow

Wheel bed carton flow consists of rows of plastic, steel, or aluminum wheels suspended between two beams. Each row of wheels mounts on a single axle. However, many wheel bed options offer bearings that allow the wheels to turn smoothly and independently of one another.

Wheel beds typically provide a pattern of alternating or staggered wheels to spread the carton weight across the bed. This ensures that no single or group of wheels takes on more weight than the rest of the bed, reducing the risk of imprinting.

Unlike full-width rollers, wheel beds offer an uninterrupted bed of carton flow across an entire level. Wheel bed carton flow is ideal for mixed carton sizes and operations with regularly changing product lines.

Wheel Rail Carton Flow

Wheel rails have plastic, aluminum, or steel wheels mounted directly within a channel. Wheel rail designs vary greatly. Wheel rails may have alternating wheel patterns or a single, vertical line of wheels.

Each wheel rail operates independently, allowing flexibility in placement and rail distance. Wheel rails are not load-bearing and require intermittent support throughout the rack. Ultimately, wheel rails work best for small, lightweight cartons. Heavier products may move the rails, become lodged within the system, or suffer damage like carton imprinting.

- Low-profile carton flow

- Keg flow

- Wheel rail carton flow

- Tilted shelving

- Roller lane

- Wheel bed lane

Carton Flow Applications

Food and beverage

3rd party fulfillment operations

Automotive part suppliers

Distribution centers

Small parts handling

Manufacturing

Pharmaceuticals and Healthcare

Retail

Carton Flow Cost

On average, carton flow costs $500 to $1,000 per 8’ wide x 8’ deep storage level. Remember that carton flow is a customized storage solution that varies from one project to the next. Each customized system involves careful testing, individualized components, and installation that will affect the end cost.

Certain carton flow systems are advantageous over others depending on the application and product. If you want a gravity flow system for your warehouse, call 800-722-5908 or fill out an online quote form to get started!

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.