Selective pallet rack is the most common storage system for warehouse pallet storage. This bare-bones pallet rack solution consists of vertical frames and horizontal beams that lock together to form sturdy shelving for palletized material in a warehouse. Selective pallet racking is called “selective” because it offers high levels of selectivity and forklift accessibility to each individual pallet stored within the system. In other words, they are called “selective” because this type of pallet rack allows workers to select any pallet from anywhere in the pallet system without moving any other pallet.

Selective pallet racking is well-suited for warehouses with many different products but a relatively low quantity of each SKU. This storage system provides efficient space utilization and is especially beneficial for high inventory turnover, offering quick and efficient access to individual pallets.

Advantages of Selective Pallet Racks

Selectivity: Selective pallet racking offers direct access to each pallet within the system.

Versatility: Selective rack is highly customizable and easy to adjust as demands shift. Bolster your selective rack system with column protection, pallet rack decking, or other safety products.

Compatibility: Most teardrop pallet rack styles are compatible with one another, making it easy to add to your current rack system or replace components even if the same brand of racking is unavailable.

Strength: Selective pallet rack is sturdy enough to handle heavy-duty loads (from 10,000 to over 50,000 pounds) and can be custom-manufactured for applications requiring high-strength steel.

Cost-Effective: In general, selective pallet racking is the least expensive pallet rack option available on the market.

Easy Assembly: Selective pallet racks are quick and easy to install. Most pallet rack beams lock into frames and are secured with safety clips. Learn more about pallet rack installation.

Easy Reconfiguration: Easy to reconfigure for increased storage density or a more efficient warehouse layout.

Reduced Handling Time: Forklift operators can quickly and easily load or unload pallets from selective pallet rack systems.

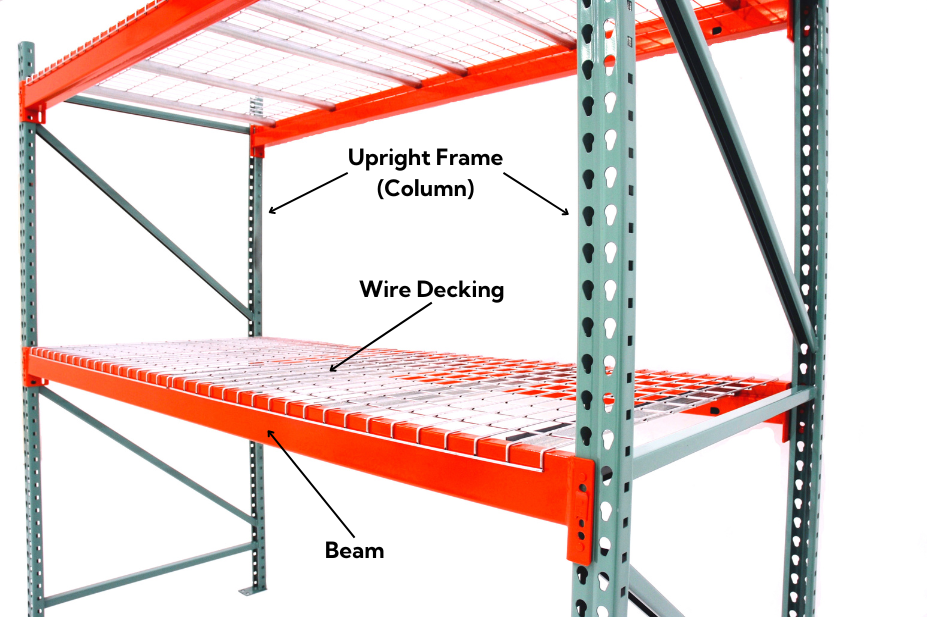

Selective Pallet Rack Components

Every selective pallet racking system is comprised of numerous bays of pallet racking. A single selective pallet rack bay typically comprises the following selective pallet rack components: Upright frames (columns), beams, wire decks, and safety accessories (optional).

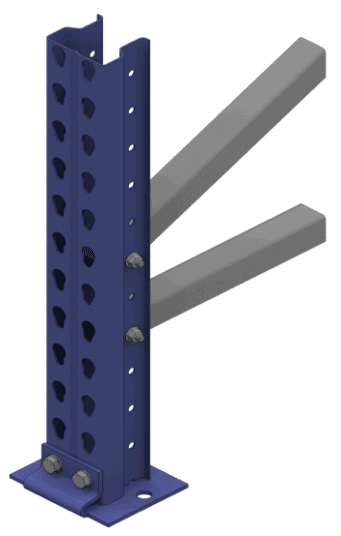

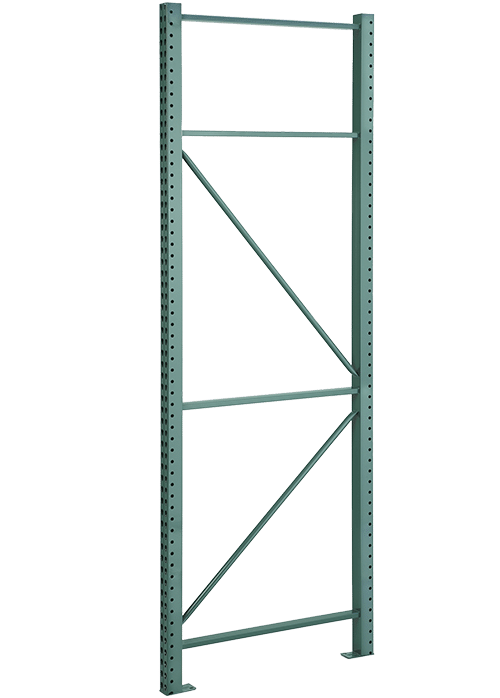

Pallet Rack Frames

Pallet Rack Frames, commonly called “uprights” or “columns,” are the vertical structures to which pallet rack beams connect. Two uprights are required per bay.

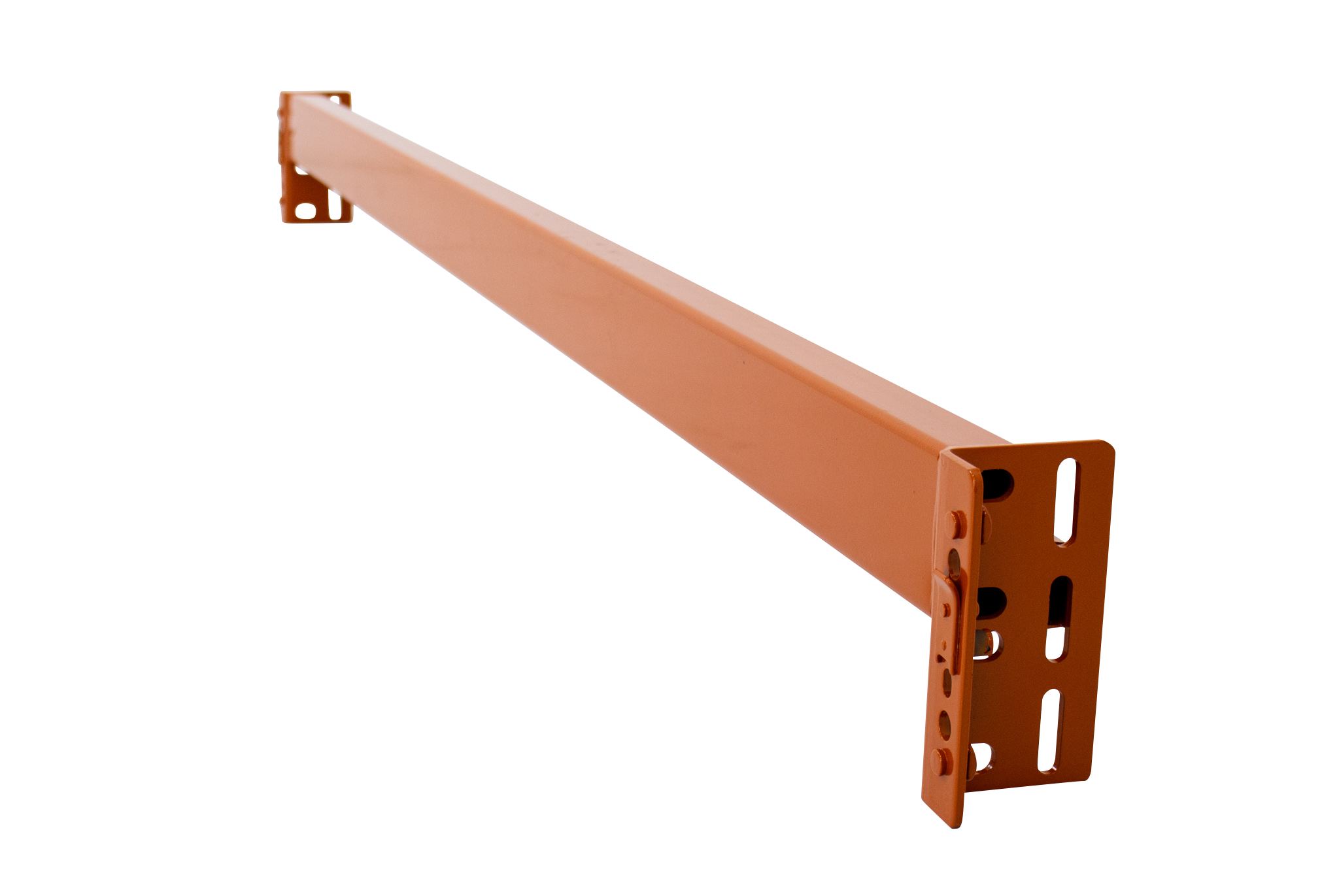

Pallet Rack Beams

Pallet rack beams are the horizontal “shelf” components that lock into the frames. Two beams are required per shelf level, and four are needed to create a structurally viable pallet rack bay.

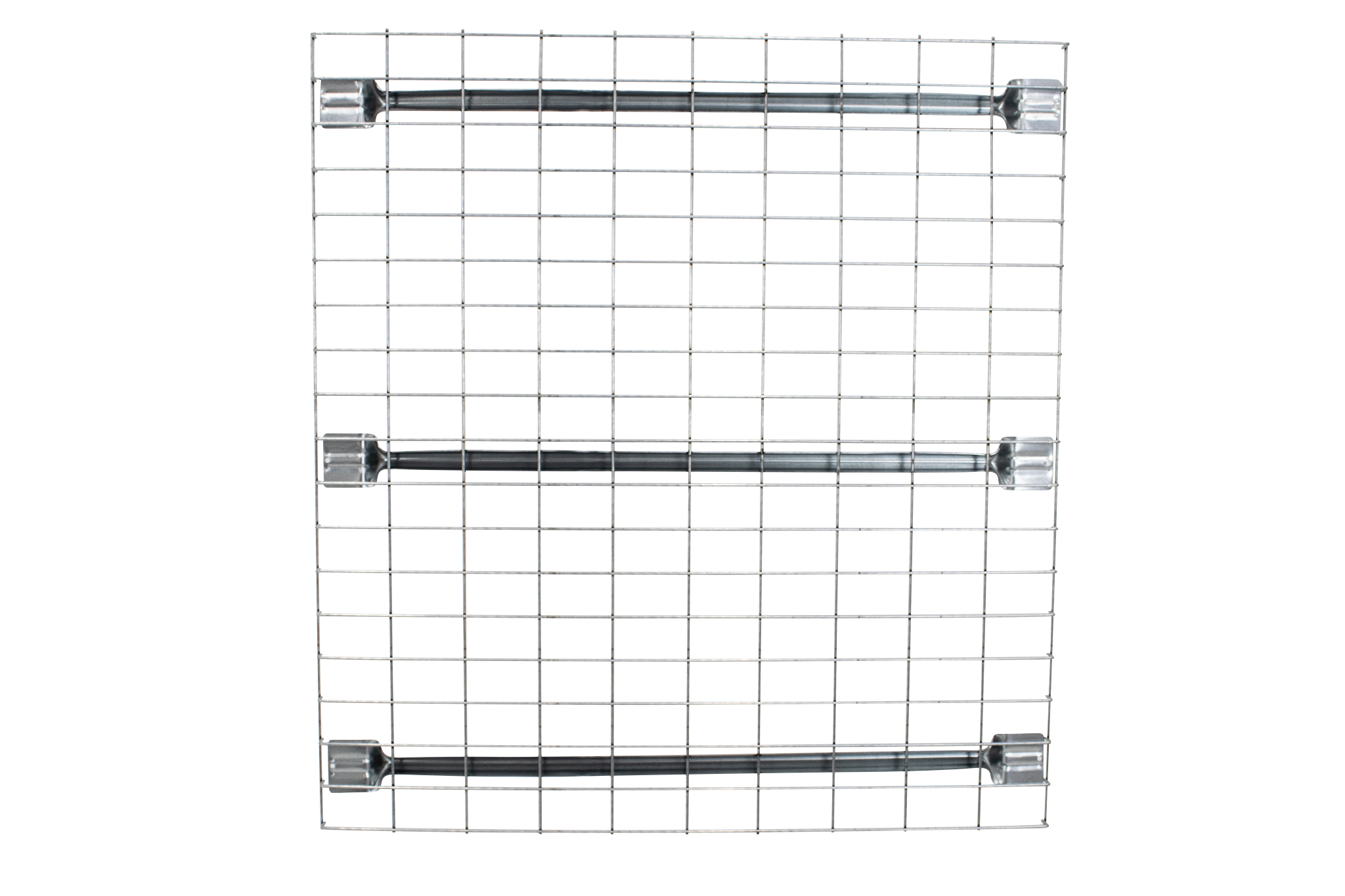

Pallet Rack Wire Decks

Pallet rack wire decks are an optional decking option used in many selective pallet racking systems. Wire decks lay flat across the two beams of each shelf level, creating a flat surface for pallets or boxes, preventing them from falling through the beams.

Pallet Rack Safety Products

Selective pallet racking can be bolstered with safety products like column protectors, safety rails, rack backing or safety netting, and more. Visit our warehouse safety guide for a complete list of pallet rack safety products and customization options.

Shop Pallet Rack Components Online

If you know what you need and want to purchase pallet rack components today, call 800-722-5908 or shop online at our e-commerce division, Pallet Rack Now.

Types of Selective Pallet Racking

Selective pallet racking is manufactured in multiple styles, each of which offers its own unique advantages. The two main types of selective racking are roll-formed and structural. Roll-formed racking is either welded or bolted, while structural is exclusively welded. The styles of selective pallet racking include:

- Roll-formed: Roll-formed pallet racking is manufactured by cold rolling steel sheets into the desired shape. Each additional bend in the steel increases the rack’s strength and rigidity.

- Structural: Structural pallet racking is built with sturdy, thick steel, and components are typically bolted together. Structural racking offers more damage resistance and higher load capacities.

- Welded: Welded pallet racking offers greater rigidity because joints are securely welded together rather than bolted.

- Bolted: In bolted pallet rack systems, components such as footplates, bracing, and end connectors are bolted together rather than welded. This allows for easy reconfiguration and replacement of damaged parts.

- Galvanized: Galvanization is a type of finish that involves dipping pallet rack components in melted zinc to create a corrosion-resistant coating. Galvanized pallet racking is suitable for outdoor applications and more.

- Stainless Steel: Stainless steel pallet racking is made entirely of stainless steel, which is inherently corrosion-resistant, sanitary, and heavy-duty.

- Closed Tube: Closed tube pallet racking components (frames and beams) are fully enclosed and typically offer higher capacities.

- Open Tube: Open tube pallet racking components are open on one side, allowing easy cleaning, which is great for sanitary applications. This style is more straightforward to manufacture.

Roll-Formed

Structural

Welded

Bolted

Galvanized

Stainless Steel

Closed Tube

Open Tube

Selective Pallet Rack Manufacturers

We partner with many selective pallet rack manufacturers. See our selective pallet rack partners below and visit our pallet rack identifier to identify which brand of pallet racking you have.

- Interlake Mecalux

- SpeedRack Products Group

- Nucor (Hannibal Industries)

- Nashville Wire Products

- Nelson Wire and Steel

- J & L Wire Cloth

- Ridg-U-Rak

- Tri-Boro

- SpaceRak

- Heartland Steel Products

- Unarco Material Handling

- Bulldog Rack Company

- Steel King Industries

- ITC Wire

- Husky Rack & Wire

Pallet Rack Quick Ship Nationwide

We stock and ship pallet rack nationwide! Because we own all of the products in our two main warehouses, we can offer quality US pallet racks with a quick turnaround. Orders typically ship within 24-48 hours, and our pallet rack design specialists help ensure that you get the right pallet racking for your storage needs. To see our quick ship selective pallet racking, visit our in-stock pallet rack page.

AK Material Handling Systems is a major stocking distributor of new selective pallet rack systems headquartered in Maple Grove, MN, with an additional warehouse in East Stroudsburg, Pennsylvania. At our two main warehouses, we stock a variety of selective pallet rack manufacturers, including Speedrack, Spacerak, Steel King, Ridg-U-Rak, and Interlake, to ship across the United States.

We have one of the world’s largest in-stock pallet rack inventories and partner with several manufacturers to ship pallet rack products nationwide. We direct ship out of California, Wisconsin, Arizona, Ohio, North Carolina, Michigan, and Georgia. For pricing and availability, please use our pallet rack quote request form or call 800-722-5908.

How to Measure Pallet Rack

When measuring your pallet rack system, it is essential to consider pallet rack capacity. Choosing the right pallet rack components involves finding the correct size and capacity to hold your product safely. Learn more about regulation adherence when measuring pallet racks and choosing your pallet rack capacity.

Pallet Rack Upright Frame Information

How to find the right pallet rack uprights?

Capacities are based on 48″ beam spacing. Depth of frame should be 6″ less than pallet length. For example, a 48″ deep pallet requires a rack with 42″ depth.

Frame measurements: frame height = (height of pallet + height of beam+ 4″ vertical clearance) x number of levels.

Pallet Rack Cross Beam Information

How to find the right pallet rack beams?

Correct beam length for your application is calculated by adding together the widths of the pallet loads, 5″ side clearance between the uprights and pallets, and a 6″ space between pallet loads.

Example: pallet width= 40″

40″(Pallet) + 5″ (Side clearance) + 40″ (Pallet) + 5″ (Side clearance) + 6″ (Between Loads) = 96″ Beam

Beam measurements: Length equals the total distance between uprights. Height is measured from the top to bottom of the front side of the beam.

Pallet Rack Wire Deck Information

How to find the right pallet rack wire decks

To find the right wire deck measurements for your pallet racking system, we will need to know the out-to-out depth of your frames and the length of your beams. When measuring your beams, measure from the inside of the left upright to the inside of the right upright or between the vertical uprights. You will also need to identify your type of beam – is it a step beam or box/structural beam?

For more specific wire deck measuring instructions, check out our wire deck ordering blog.

Aisle Width Information

How to find the right space between pallet racks for forklifts

The type of forklift used determines the warehouse aisle width required for efficient and safe storage operations. Other factors that play into aisle width and warehouse layout include:

- Product type

- Pallet type

- Pallet sizes

- Quantity of pallets

- Available storage area

- Clear heights

- Type of loading docks

- And more

Selective Pallet Rack Cost

On average, selective pallet rack costs $70-$100 per pallet position. However, pallet rack price varies significantly by component, capacity, pallet rack material, and installation labor. Installation costs can vary by pound and other determining factors.

Contact a Warehouse Design Specialist

If you are ready to purchase a selective pallet rack system for your warehouse, we can help! Our pallet rack design specialists have the knowledge and tools to create your custom warehouse layout design. Call 800-722-5908 or complete a quote form to start your warehouse design journey today!

What Customers are Saying About Us

“We ordered pallet racks and shelves for our warehouse. The sales associate was very knowledgeable and helpful. We shopped around on pricing and AK Material was the best by far with excellent quality as well. The shipment arrived 3 days sooner than expected which was wonderful! We will use them again!”

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.