If you’re in warehouse management in the oil and gas industry, you may be looking to optimize your current warehouse’s efficiency or build a new warehouse. AK designs code-compliant oil and gas warehouses and can provide flammable liquid storage systems.

Keep reading to learn how to store flammable oil and gas products and get connected with a solution today.

Proper Handling and Storage of Fuel and Oil

Flammable Liquid Storage Regulations

To store flammable liquids like oil and gas, warehouses must adhere to fire safety codes established by regulatory agencies. The Occupational Safety and Health Administration (OSHA) and the National Fire Protection Agency (NFPA) require specific storage conditions and handling processes for flammable liquids to prevent fire-related disasters at storage facilities.

When storing hazardous materials, learn the general and region-specific storage regulations in your area. Adhere to these regulations while choosing pallet racking and other storage equipment.

Specified Fire Areas

Fire barriers separate flammable liquids from other materials in a warehouse. These walls must be implemented in warehouses that store and handle flammable materials to contain potential fires or explosions.

Inside enclosed hazard areas, warehouse personnel must take extra precautions. Flame or electrical sources like cigarettes, charging stations, welding or cutting tools, and heat or spark-producing machines are prohibited. Specified fire areas and walkways should be kept clean and free of trip hazards.

Learn your area’s allowable square footage and gallons per square foot for flammable liquid storage rooms. For example, liquid storage rooms typically cannot exceed 500 square feet, and the allowable liquid storage limit is measured in gallons per square foot.

The degree of implemented fire protection can alter the storage capacity of a flammable liquid warehouse.

Signage and Labeling

All flammable and combustible liquids have unique fire characteristics. According to OSHA, warehouses must store each material according to its labeled fire characteristics. Typically, flammable liquids will be marked with their tendencies and hazards to assist with storage and handling. All hazardous materials must be labeled appropriately.

Hazardous areas in a warehouse must be marked with signage and tags to increase awareness. There are specific colors that specify fire or explosion hazards.

OSHA specifies that red, white, and black signs must be placed in danger zones. Yellow and black signs should be placed in areas where caution is advised. To read more on OSHA signage requirements visit the laws and regulations portion of the OSHA website.

Explosion-Rated Tools and Equipment

Warehouses can use explosion-proof equipment within flammable storage environments. Flame-resistant lift trucks, shuttle systems, safety cans, storage racking, safety cabinets, and more are available and approved for combustible storage warehouses. Fire-rated equipment must be labeled and easily identifiable.

The Top 5 Oil and Gas Warehousing Issues

Warehousing is a vital part of the oil and gas industry. Proper warehousing can bolster production and distribution processes, optimizing every sector of the industry. That said, here are some of the top issues facing oil and gas warehouses today:

Lead Times

Unpredictable lead times can result in late deliveries, halting oil rig operations altogether. Oil producers lose huge amounts of money when rigs are not operational.

Stock

Stock levels affect warehouse product flow, lead times, and deliveries. Keeping an accurate record of available stock, and a handle on product flow to and from the warehouse is vital to industry success.

Warehouse Layout

Oil and gas warehouses are essential, fast-moving storage operations. The physical layout of the warehouse greatly influences efficiency and production capabilities. An inefficient layout can seriously hinder a warehouse’s daily output.

Warehouse Protocols

Poor warehouse protocols pose a threat to a facility’s production capabilities and the oil and gas supply chain as a whole. Oil and gas warehouses should strive to optimize workflows and decrease waste in every facet of their daily operations.

Warehouse Location

A warehouse’s location in relation to oil rig sites and end-of-line customers is actually quite important. Both location and ease of access affect input and output numbers.

What Material Handling Equipment is Needed for Oil and Gas Storage?

There is different fire-rated storage equipment for different needs. Some of the most common equipment found in oil and gas storage facilities include:

- Signage

- Guarding

- Explosion-proof forklifts

- Pallet racking

- Safety cans

- Wire partitions

- Flammable storage cabinets

- Flammable safety lockers

- Wire products

- Conveyors

Oil and Gas Storage Solutions (AK Provides)

At AK Material Handling Systems, we offer oil and gas storage solutions so you can safely store flammable liquids. Below are some of our oil and gas warehouse automation offerings, as well as standard storage systems and safety products.

Warehouse Automation Solutions for Oil & Gas

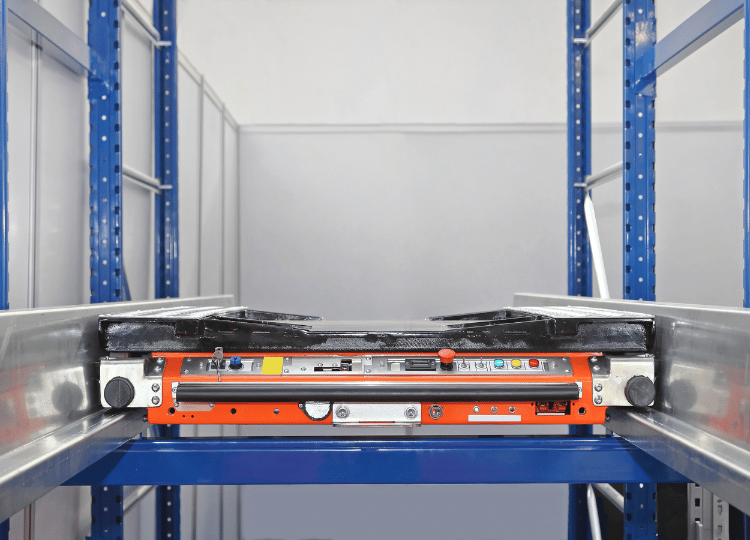

Warehouse automation helps speed daily processes but can be dangerous in a flammable environment. Motors, batteries, and moving parts can create sparks or explosions. For oil and gas warehouses, explosion-proof automation is a viable option.

We offer explosion-proof shuttle systems, warehouse cranes, forklifts, and more and can help you find the best automation options for your warehouse.

Storage Solutions for Oil & Gas

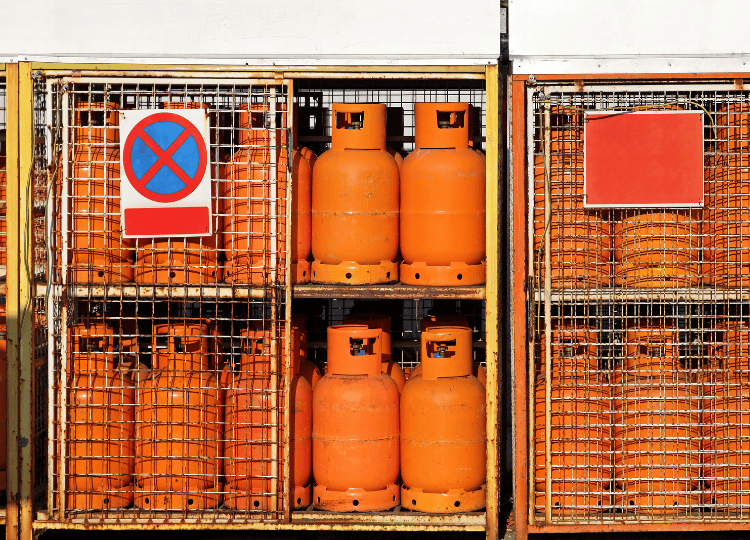

Flammable liquids like oil and gas are typically stored in cylindrical canisters or drums. Cylinders already require specialized storage systems, and flammable cylinders come with a whole separate list of regulations.

Some of our cylinder storage offerings include flammable storage cabinets, gas cylinder storage, drum cradles, wire partitions, and more.

Safety Products

AK offers a variety of safety products for oil and gas warehouses including safety rack guards, bollards, signage, machine guards, and more. Contact us to learn more about oil and gas storage and safety options.

Contact a Warehouse Designer to Get Started

Let AK Material Handling Systems help you plan your oil and gas warehouse – call 800-722-5908. Our warehouse design experts can help design a code-compliant storage plan for your unique application and needs.