Industrial work platforms and mezzanines are elevated platforms that increase functional warehouse space by up to 75%. Mezzanines add new levels of work, storage, or office space in a facility and prevent the need for expensive warehouse relocation or construction.

Warehouse work platforms easily integrate into any space and are highly customizable. These code-compliant industrial work platforms are cost-effective, durable, and easy to install. To speak with a design specialist about adding a mezzanine platform to your warehouse design, call 800-722-5908 or fill out an online quote form.

Mezzanines Vs. Work Platforms?

“Mezzanine” and “work platform” are synonymous. Both terms refer to the same system and will be used interchangeably throughout this page. These platforms are also known as lofts, standing platforms, storage platforms, and equipment platforms.

On the other hand, mezzanines may be mistaken for mezzanine floors or balconies (as is commonly seen in concert halls and venues). Both of these serve as elevated functional spaces, but AK Material Handling Systems deals solely with warehouse mezzanines.

Care must be taken in the terminology used in the permit application, as this could trigger sections of building code that are not necessary.

Advantages of a Work Platform

Space Utilization: Work platforms maximize vertical space, providing extra material storage and functional warehouse space.

Cost-Effective: Adding a work platform saves companies up to 80% on their storage expansion costs compared to alternatives like a building addition or relocation. Mezzanines offer significant tax advantages.

Customizable: Work platforms are fully customizable for any environment or application. Find more information on customization options below.

Versatile: Mezzanines host various processes, from static storage or designated pick and pack zones to office space or breakrooms.

Durable: Work platforms are constructed from heavy steel and are securely bolted to the warehouse floor. Their design should withstand even the most demanding environments.

Safe: These industrial work platforms have safety guardrails, non-slip surfaces, and other safety features to prevent hazardous environments.

Code-Compliant: Work platforms meet OSHA and ADA requirements and satisfy even the convoluted regulations in seismic zones.

Warehouse Mezzanine Manufacturers

- Bluff Manufacturing

- Cogan

- Nucor (Hannibal)

- Heartland Steel Products

- Konstant

- Steel King

- UNARCO

- Western Pacific Storage Solutions

- Wildeck

Types of Mezzanine Platforms

Freestanding Work Platforms

Freestanding work platforms are self-supported and can be placed anywhere within a warehouse. Four heavy-duty steel columns support the structure. Free standing mezzanines can move if needed.

Rack-Supported Mezzanines

Rack-supported work platforms are designed within existing pallet rack systems and directly above working aisles. The platform bolts to the upright columns and creates new storage space in a warehouse.

Shelving-Supported Mezzanines

Like rack-supported mezzanines, shelving-supported mezzanines are secured to existing shelving for storage and handling space below and above the platform.

Building-Supported Mezzanines

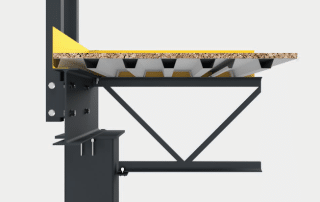

Building-supported mezzanines attach to a building’s architectural framework – typically protruding from an outer wall. Like all work platforms, building-supported work platforms create additional floor space and facility flexibility.

Catwalk Work Platforms

Generally, catwalks provide runway access from one elevated surface to another. They often serve as maintenance or inspection access.

Multi-Level Work Platforms

Some work platforms have two or even three unique levels. The number of vertical levels depends on building codes, capacity, ceiling height, and intended use.

Work Platform Customization Options

When designing a warehouse mezzanine, there are many customization options. Businesses should choose each component based on the application at hand. Equipment platform customization options include:

- Framing: Mezzanine framing is the essential support structure that affects any work platform’s size and capacity limits. Framing options for mezzanines, from smallest to largest size and capacity, include bolted c-sections, beam & c-section, beam & beam, beam & bar joist, and truss girder & bar joist.

- Stairs: Common mezzanine stair customizations include stair orientation, number of landings, dimensions, and material (steel, aluminum, or other alloys). Additionally, warehouses must select the tread and riser design, proper non-slip surfaces, and handrails for application. Different stair types include welded, knockdown, and modular staircases.

- Access gates: Mezzanine access gates come in many styles. Standard gate styles include swing gates, slide gates, lift-out gates, tilt gates, impact gates, and pivot gates. More industrial mezzanine safety gates include pivot, double-drop, overhead, and pallet drop zone gates.

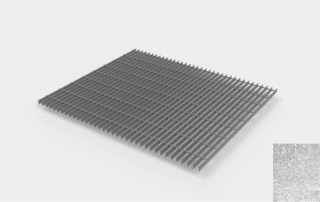

- Decking and flooring: Common mezzanine decking options include steel grating, resin board, plywood decking, bar grating, solid steel plates, open-deck, fiberglass grating, perforated steel decking, diamond plate, grated decking, full mat flooring, or combination decking.

- Lift type: When needed, mezzanine lifts include automated tote lifts, modular box lifts, hydraulic lifts, mechanical modular lifts, and Vertical Reciprocating Conveyors (VRC).

- Guardrail systems: Guardrails prevent deadly falls or falling items. Common guardrail options include standard guardrails, picket guardrails, mesh or wire mesh guardrails, toeboard extensions, kickplates, adjustable guardrails, collapsible guardrails, and more.

- Platform size: Platform size is determined by available warehouse space, storage, and capacity needs. The height, footprint, and capacity are all size factors to consider in a design.

- Capacity: Work platform capacity is influenced by the structural design, load distribution, column size, column material, column spacing, floor material and thickness, connection methods, and live vs. dead loads.

Code-Compliant Warehouse Mezzanines

Work platform compliance is governed by the International Code Council (ICC), the parent organization that supervises several codes, including the International Building Code (IBC). Section 505 of the IBC specifies requirements for mezzanines and equipment platforms.

These specifications dictate platform floor area, means of egress for steel mezzanines, clear height, and other work platform specifics.

IBC codes are updated every three years. Strict adherence to current IBC codes in your region is essential and will ensure continued compliance and safety for your employees and facility.

Warehouse Mezzanine Applications

Storage and Shelving

Order Picking and Packing

Office Spaces

Dust cover

Tool crib

Retail Backrooms

Assembly and Manufacturing

Distribution Centers

Security Enclosures

Lunch/Break Rooms

Access and Maintenance

Automotive Dealerships

Gyms and Fitness Centers

How Much Does an Elevated Work Platform Cost?

On average, equipment platforms cost $85-$115 per square foot, including installation. Many factors, including steel gauge, platform capacity, size, and customizations, influence the overall cost of an installed work platform.

To get a custom quote, complete an online quote form or call 800-722-5908 today. One of our warehouse design specialists will happily assist you with your elevated workspace design and installation!

Again, be sure to work with your design specialist to determine which terminology to use in your permit application for applicable building codes and regulations.

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.