What is Push-Back Racking?

Push-back racking is a high-density, gravity-driven pallet rack system that easily integrates with any selective pallet rack design. The innovative rolling cart and rail design helps push-back optimize warehouse operations without slowing product rotation or increasing handling time. With a push-back racking system, warehouses can store more pallets while retaining more pick faces than lower selectivity systems, such as drive-in pallet racking.

Compared to standard selective racks, a push-back rack system can offer up to 15%-50% more storage space. With this increase in storage density, you can also expect the push-back pallet rack price to increase. Still, many warehouse managers find push-back racking a worthwhile investment over time.

If you’re looking for high-density storage or more information on push-back pallet racks for your warehouse, call 800-722-5908 to contact one of our pallet rack design specialists.

How Push-Back Racking Systems Work

Push-back racking systems store pallets on rolling pallet carts that rest on a set of inclined rails. Push-back racking utilizes the force of gravity to pull pallets to the loading/unloading pick face. This slight incline enables forklift operators to load pallets onto the carts and push them up and back as the next pallet is loaded.

When unloading push-back racking, the pallet being unloaded acts as a brake for the pallets behind. After removing the first pallet, the next one behind it rolls to the pick face for unloading. Watch the video to the right to see push-back pallet rack in action.

Push-back racking systems are highly conducive to storing SKUs with multiple pallets, and each lane can accommodate anywhere from two to six pallets depending on the weight of each pallet and the push force of your forklift. Push-back systems work with all forklifts, including counterbalance, narrow-aisle, and swing-reach forklifts.

Because each pallet lane operates independently, push-back pallet storage is more versatile than drive-in racking. In a push-back pallet rack system, fork or lift trucks never actually enter the rack system, reducing the possibility of forklift damage to the racking.

Advantages of Push-Back Rack Systems

Push-back racking offers numerous value-adds for warehouses with multiple pallets of the same SKU.

Here are the primary push-back racking advantages:

Space Utilization: Push-back racking systems provide better use of available warehouse space than standard selective racking. This storage system stores more pallets while eliminating aisles

SKU Density: Push rack allows storage of more SKUs with its deep-lane, single-aisle design

Accessible: Forklift drivers do not have to remove blocking pallets to reach a specific SKU

Efficient: Quick & easy loading and unloading of pallets

Low-Maintenance: Push-back carts are relatively low-maintenance, with protected sealed bearings

Customizable: Pallet carts and racking are customizable by color, cart style, cart profile, rack style, steel finish, column protection, and more.

Safe: Forklifts never have to enter the push-back rack system, which prevents rack damage

Push-Back Pallet Rack Carts

Different push-back pallet rack carts exist for different pallets and storage applications. Push-back cart and rail systems are custom-designed around a loaded pallet. Manufacturers typically require a loaded pallet to test with because push-back racking depends on proper capacities and functional pallets.

The pallet determines the cart’s shape, size, profile, wheel style, etc. The storage application also plays into these factors, including steel finish and other environment-dependent customizations.

Cart Customization Options:

- Color: push-back carts are typically color-coded by height

- Mesh supports: full mesh supports can be added to your carts to provide better support to weak or damage-prone pallets

- Size: extra long or extra wide carts are available to accommodate different pallet sizes

- Profile: low-profile carts are a popular space-saving option. These carts stack tightly together, saving up to 6 inches of vertical storage height per level

- Wheels: large, coated wheels allow carts to roll smoothly. There are multiple wheel options available.

- Finish: certain custom cart materials and finishes exist for cold storage, freezer, or other unique environments.

- Covers: Covered carts are available for pallets that vary in size or type and allow them to be stored in the same system.

- Links: Linked carts prevent stray or runaway pallets.

Push-Back Pallet Rack Manufacturers

We partner with many push-back pallet rack manufacturers. See our push-back pallet rack partners below and visit our pallet rack identifier to identify which brand of pallet racking you have.

- Engineered Products

- 3D Storage Systems

- Advance

- Bulldog Rack Co.

- Frazier Industrial Company

- Nucor (Hannibal)

- Heartland Steel Products

- Interlake Mecalux

- Konstant

- Mallard Manufacturing

- Rack Builders Inc.

- Ridg-U-Rak

- Speedrack

- Steel King

- UNARCO

Push-Back Pallet Rack Applications

Food and beverage

Grocery

Consumer packaged goods

Pharmaceuticals

Manufacturing

E-commerce

Logistics

Government

Cooler or freezer applications – may require stainless steel, galvanization, or another custom finish

Any application that has multiple pallets of the same SKU

10 Things to Know about Push-Back Pallet Racking

- Most forklift operators believe push-back is easier to operate than standard pallet racking. It typically takes 4 hours to become thoroughly acquainted with the rack system.

- Because forklifts never enter a push-back system, damage to uprights is much less common.

- Push-back aisles usually only need to be 6″ wider than the manufacturer’s minimum aisle requirement.

- Push-back requires little to no maintenance besides standard pallet rack safety checks.

- Push-back racks are compatible with counterbalance, reach, deep reach, swing reach, and even clamp forklift trucks.

- The standard push-back capacity is 3000 pounds per pallet position, but higher capacities are possible upon request.

- The most common pallet style in a push-back system is the standard GMA pallet, but push-back can accommodate various pallet styles.

- Typically, push-back will require an additional 6″-8″ height compared to standard selective.

- Push-back warehouse racking is often used in combination with other types of pallet racking to maximize space.

- Unless noted, most push-back rack systems in the US use structural racking. Structural pallet racking is sturdier than its roll-formed alternative. Roll-formed push-back is less common and may require double-column frames for additional strength.

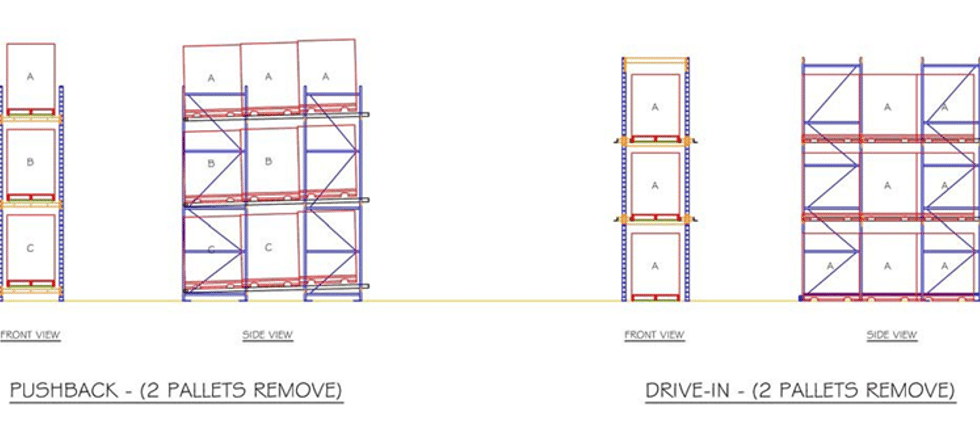

Push-Back Vs. Drive-In Pallet Racking

Push-back is often described as a better system to drive-in racking because you can get selectivity with density storage. Drive-in works best when all the pallets are the same product, whereas push-back offers selectivity with different SKUs in the same pallet rack bay.

Another advantage of push-back vs. drive-in is that you don’t have to drive into the bay as all pallet locations are adjacent to the warehouse aisle, and the pallets roll forward to the aisle. This reduces potential damage to the pallet racking system and reduces labor costs and personnel time retrieving pallets.

Push-Back Pallet Rack Cost

Push-back pallet racking costs an average of $250-$500 per pallet position. This number is over double the price of standard selective pallet racking price, which typically costs $70-$100 per position. However, warehouses that choose to implement push-back racking find that the storage density and efficiency benefits outweigh the cost of the system.

How to Maintain Push Back Pallet Racks

Safe Loading

The first pallet loaded into a lane always goes on the highest available rack cart. Forklift operators should lift the pallet at least one inch above the footplate. It is vital to keep the pallet level when loading and unloading. Once set, the pallet should be centered on the cart — make sure it’s not resting on the push plate. The storage lane is full when the push plate is no longer visible.

Safe Unloading

The most important rule to remember when using a push-back racking system is that the forklift is the only brake when removing a pallet from the rack. As the forklift removes the front pallet from the lane, each subsequent pallet on the rack slides forward. If the forklift pulls away too quickly, the remaining pallets could slide forward with too much momentum, which could cause them to tip or fall. To avoid damaged freight or personal injuries, unload slowly and steadily.

Maintenance

Push-back pallet racking systems require little to no maintenance, although we always recommend monthly pallet rack safety checks to ensure all of your racking is in safe condition. When inspecting push-back systems, look for damaged frames, loose anchors, damaged carts, broken pallets, damaged wheels, and anything that could cause the carts to malfunction.

Frequently Asked Push-Back Pallet Rack Questions

Push-back pallet racking utilizes a series of nested carts to store up to six pallets per lane. Pallets sit atop these carts, and when a pallet is loaded, the pallet positioned at the pick face is pushed backward, along with any pallets behind it. The new pallet is set on the cart that was nested below. Likewise, when pulling a pallet from the pick face, the pallet(s) behind it move forward one position.

The most significant advantage of push-back pallet racking is its ability to offer both selectivity (access to different pallets/SKUs) and storage density by storing multiple pallets per position. Because of this attribute, push-back pallet rack has steadily gained popularity in warehouses in recent decades.

The main pushback pallet rack disadvantage or limitation is its cost and low inventory rotation abilities. Pushback does not suit every application – especially those requiring strict FIFO (first in, first out) inventory management.

Push-back pallet rack systems are ideal for warehouses that store a high volume of product, have a limited number of pallets per SKU, and have a high turnover volume. However, they are only suitable for some warehouses. It is always advisable to consult a pallet rack professional to help assess your needs and recommend which system will work best for your application.

Customized push-back pallet rack systems are, in fact, available, making an already custom-engineered system even more individualized to unique applications. Manufacturers can create push-back systems to accommodate special pallets, such as extra-long and extra-wide pallets and pallets that are not strong enough to support themselves. In the latter situation, push-back carts are outfitted with full mesh supports to create additional surface area.

Yes, pushback racking is compatible with selective rack and other pallet rack systems. Contact a design professional to learn which storage styles are compatible with pushback.

Pushback racking is fully accessible from outside the system, while drive-in racking requires forklifts to enter the system to place and retrieve pallets. Both drive-in and pushback systems are LIFO (last in, first out) storage solutions.

Pushback rack aisles should be 6” wider than the manufacturer’s minimum aisle width requirements.

Helpful Push-Back Videos

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.