How does a warehouse manager make the best possible use of the space he or she has to work with? If the answer to this question was easy, there would be a lot of people out of a job tomorrow morning. Like any technical question, there’s a hefty number of factors to consider. “What are the dimensions of the building?” “What kind of products are being stored?” “At what rate do these products rotate?” These questions, while important, also lead us to a broader, more overarching question that is at the root of all others: how can I get the most value?

In the end, maximizing value is what it’s all about. Virtually every step taken by a given business is done so to either directly or somehow indirectly maximize value for the company. Trying to maximize the value of a warehouse is no different. Invariably, the warehouse manager or whoever is in charge of warehouse operations will try to determine the steps that will, in the long run, support the welfare of the company.

In all likelihood, one of the factors that will be considered will be the material handling systems in place in the warehouse, such as the pallet rack system(s). Once again, questions will arise — “How much will it cost to install a new system?” “How well will this racking let us utilize the available storage space?” “Will we need any new equipment?” On the AK Material Handling Blog, we’ve got a lot of material covering questions like these. Needless to say, there are certain rack systems that present “value” in some of its traditional forms. Take, for example, drive-in rack systems.

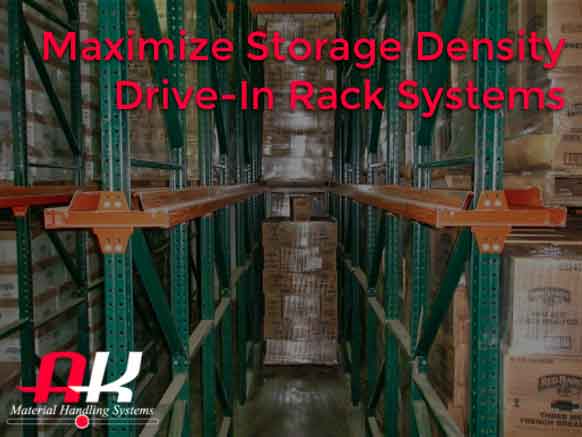

Drive-in rack systems certainly aren’t for every warehouse — far from it. Drive-in systems consist of upright frames and loading rails, as opposed to cross beams. This allows forklift operators to drive into the system itself. In most drive-in rack systems, pallets can be stored as many as 10 deep. However, this also means that the pallets that were first loaded into the system will be difficult to access because there will be so many other loads closer to the loading bay that would have to be moved. Because of this, drive-in rack systems need to store like-product. In addition, these products cannot be time-sensitive. The first pallets in will be the last ones out, so they have to be able to stay a while. Despite these requirements, there is a lot of value to be gained from drive-in rack systems for those whose warehouses fit the above criteria.

For one, drive-in systems are a relatively low-cost means of storage. It probably won’t be necessary to delve into the obvious appeal of lower costs here. Drive-in rack systems also feature enhanced rigidity when compared to many of their other rack system counterparts. That’s a good thing because driving a forklift into the rack system might otherwise present a safety hazard (it is still important to pay particular attention to the health of the drive-in rack system because of this factor). Where drive-in rack systems truly offer value, though, is in the storage density that can be achieved through their use. Because pallets are stored back-to-back in drive-in systems, the majority of access aisles can be eliminated. Floor space that would have otherwise been dedicated to aisles is now occupied by several pallets of product. Thus better, more efficient use of warehouse space is made, and additional floor space is opened up in the warehouse, potentially eliminating the need to for expansion. Herein lies the most significant value offering from drive-in pallet rack systems.

No, drive-in rack is not for every warehouse. But neither is any other pallet rack system. Each engineered rack system has its strengths and weaknesses. Drive-in rack has poor selectivity and requires that time-insensitive, like-products be stored within it. Its strengths, however, are that it is inexpensive, sturdy, and, most importantly, allows for maximum warehouse space utilization. These strengths have a lot of potential positive implications and should be given consideration when evaluating which rack system might bring the most value for a given warehouse.

If you are interested in budgetary numbers for a Drive-In Pallet Rack in your warehouse or if you are interested in more information on Drive-In Pallet Storage Systems use this request form and we will be happy to help you.

Thanks for reading – we’ll keep you posted with more useful information bits and AK updates.

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908