Welcome back for another warehouse safety article in my “Sandy’s Warehouse Safety Blog Series”. Today we are partnering up with Kyle Thrill from Toyota Lift of Minnesota to discuss the 5s theory.

5s and the Need to Package Common Sense – By Kyle Thrill

If the title comes off as one with a little bit of an edge it comes from the initial reluctance I felt when first introduced to the practice of 5s. But first things first, “5s” is the name or the almost acronym given an approach to workplace organization. The term 5s comes from the list of Japanese words defining this work and those words of course all starts with the letter “S”. They are; seiri, seiton, seiso, seiketsu, and shitsuke. Translated to English the words also start with “S”. In the same order, those words are sorting, stabilizing or straightening, sweeping or shinning, standardizing, and lastly sustaining. Call it the poor man’s ISO 9001, OK maybe that’s too harsh, but it was a thought that struck me.

If the title comes off as one with a little bit of an edge it comes from the initial reluctance I felt when first introduced to the practice of 5s. But first things first, “5s” is the name or the almost acronym given an approach to workplace organization. The term 5s comes from the list of Japanese words defining this work and those words of course all starts with the letter “S”. They are; seiri, seiton, seiso, seiketsu, and shitsuke. Translated to English the words also start with “S”. In the same order, those words are sorting, stabilizing or straightening, sweeping or shinning, standardizing, and lastly sustaining. Call it the poor man’s ISO 9001, OK maybe that’s too harsh, but it was a thought that struck me. When I first went through the material I found there was little I could argue with, some of it seemed a bit involved but overall I could see the intent to improve the workplace environment by reducing clutter, creating known spaces for assets required, cleaning and through it all even improving safety. I was only put off by what seemed like the need to promote or hype what my Mother told me all those years ago. How odd I thought that there seems to have been an entire industry created that simply “packages” or put in a three-ring binder what Mom drilled into us day in and day out. “Pick up your room, get your things to put away, and keep it that way!” 5s, Mom you should have put it in a fancy binder and sold it as a process, you might have made a fortune.

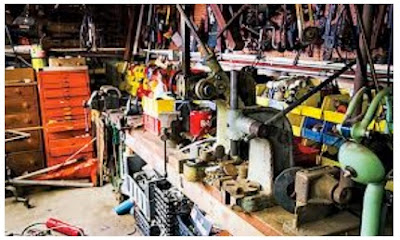

All that said the workplace is a small slice of the real world, and in that world the business of “getting things done” often has us picking and choosing where to spend our working hours, and our focus rightfully so is often getting the product or service out, and lacking the daily guidance of our mothers there sometimes the workplace looks a little less tidy than it should. Often times it can degrade to a point where it simply gets in the way of work, it’s when it reaches that point that we invite the need for the 5s program.

The 5s program has us return to what should be common sense, it packages the effort in a way that makes it let’s say easier to understand and even address. First, you start by sorting, what is needed what isn’t, finding the home for or create one for the things you require, dispose of those that you don’t. Unneeded or unused objects require space and space costs money as does constantly working around them, throw them out, or find a spot to store them. You’re then into the straightening out, a home for everything, and everything its home, and those homes should be labeled so if it isn’t there you and everyone else knows it is in use, or perhaps missing. Once things are organized you’ll find there is a lot more real estate exposed, clean it and keep it clean. Standardize, if you have work stations ensure that they are identical if a person has to work in more than one space, he or she should find that everything in that space is where it is in every other, it aids efficiency and cuts down on worker frustration. Finally, you’re looking at the important bit, keeping things the way you got them, or sustaining. Develop standards for your workplace, standards that everyone knows and understands. Standards that can be used as a guide during inspections, inspections that will go a long way towards helping you maintain the work-friendly environment that you and your coworkers have created. An environment that is easy and productive to work in.

The 5s process isn’t an easy one, and it is one that will take a commitment from everyone, from top to bottom the organization has to buy into the effort in order to make it work. But before you take that sentence as an excuse to just say “it would be nice” stop and think just a moment. Doesn’t everyone feel better when they’re dressed up? Don’t most people enjoy living in a clean house or apartment? Isn’t there a need for pride everywhere? Why not where we work?

The 5s process isn’t an easy one, and it is one that will take a commitment from everyone, from top to bottom the organization has to buy into the effort in order to make it work. But before you take that sentence as an excuse to just say “it would be nice” stop and think just a moment. Doesn’t everyone feel better when they’re dressed up? Don’t most people enjoy living in a clean house or apartment? Isn’t there a need for pride everywhere? Why not where we work? Working towards a workplace environment that is clean and organized doesn’t have to happen overnight. Working towards a space where everyone can tell at a glance where everything is, or should be done not have to be accomplished immediately. Developing a communal sense of pride among those that work and maintain the area will take time, but all the work, in the end, will bring positive results. Results in less time spent looking for things, more time spent on getting our work done. And don’t forget the wow factor. Customers, vendors, and prospective employees will know at a glance that your place means business and is in appearance as professional as the way you know its run.

Look into some of the quick references available

What You Need to Know About 5S’s http://www.qualitytrainingportal.com/resources/5S/index.htm

Download the 5S Workbook www.bradyid.com.sg/download/catalogues/5S_HandBook.pdf

A Practical Approach to the Successful Practice of 5S http://www.isixsigma.com/tools-templates/5s/practical-approach-successful-practice-5s/

Contributors: Kyle Thrill – Jason Kasanezky

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908