Amerilab Phase One

The first phase of an extensive, two-year pallet rack installation and partial relocation is now complete. This storage system primarily consists of engineered push-back pallet racking that will store raw materials for Amerilab — a local manufacturing company.

Amerilab Technologies Inc. manufactures effervescent tablets and powders and non-effervescent powders that dissolve in water for human consumption. An application like this requires sanitary and efficient storage of raw ingredients.

AK Material Handling Systems worked with this company to craft a custom storage solution for their needs. Please keep reading to learn how we met their needs in phase one and to hear our vision for completing the project in the remaining phases.

Customer Storage History and Needs

Amerilab is located in Plymouth, MN. Having outgrown its first warehouse facility, the company resorted to 3rd-party warehousing, which significantly increased storage expenses. Eventually, the growing company required even more storage and additional space for manufacturing within the warehouse, which led to the purchase of a second warehouse.

This new warehouse, also in Plymouth, will increase in-house storage and manufacturing space but requires intensive warehouse design before becoming a functional amenity for the company.

Primary Storage Goals

Amerilab’s two main goals for this storage project were to:

- Eliminate the need for 3rd party warehousing

- Expand their storage and manufacturing space

To meet these goals, the company needed professional help to complete the following steps:

- Warehouse layout and design for the new facility

- Product and pallet rack relocation from the 3rd party warehouse and some from their current facility

- Pallet rack installation

Enter AK Material Handling Systems.

Solving a Storage Dilemma With Warehouse Design

Here at AK, we offer turnkey warehousing services, including layout design, warehouse relocation, and pallet rack installation. For the Amerilab project, we provided solutions to both of their primary storage goals, completing each step of the process.

Project Details and Approach

The star of the Amerilab project is push-back pallet racking. Push-back racking is a last-in-first-out (LIFO) storage system that allows greater storage density and warehouse efficiency for companies like Amerilab, which is constantly rotating raw or perishable materials.

This storage system is mostly rows of 2 and 3-deep RBI push-back racking. The racking will store the raw ingredients and manufacturing materials for Amerilab’s dissolvable powder and tablet production.

The most pressing goal was eliminating the need for 3rd-party warehousing. We achieved this in the very first phase by designing the first half of Amerilab’s new facility, installing new and relocated push-back racking, and relocating products from the 3rd-party source. We’d call that a success!

Estimated Project Timeline

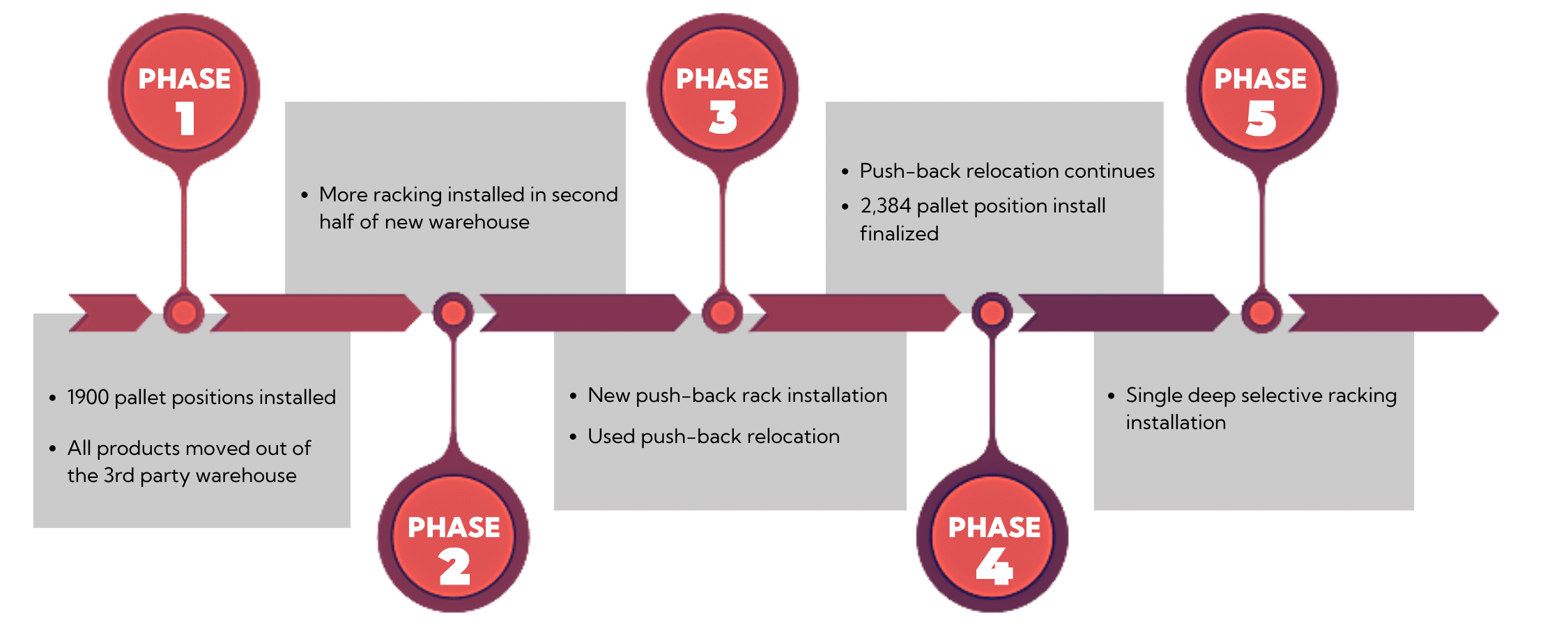

Talk of this project began in November of 2021. Phase one was initiated in Fall of 2021 and continued until the Summer of 2022. The project is ongoing and completed in stages, with a projected two years until completion. See a rough timeline and projected goal for the project below (please note: project timelines and layouts are subject to change at any time):

» Phase 1

In phase one, we designed and installed 1900 pallet positions of push-back racking in half of Amerilab’s new warehouse facility. We then moved products (raw materials) from the 3rd-party warehousing facility, eliminating the need for this service.

» Phase 2

Phase two began in the Fall of 2022 and is currently in process. This phase involves installing racking in the second half of the new warehouse, where raw material storage and manufacturing are to take place.

» Phase 3

Phase three is installing new push-back racking and relocating some push-back from the other facility for additional raw material.

» Phase 4

We will continue relocating push-back racking from the existing facility in phase four. An astounding 2,384 pallet positions will be moved and installed between phases two-four.

» Phase 5

Finally, phase five will involve the installation of Steel King single deep selective racking for miscellaneous and packaging storage – approximately 1,000 pallet positions in three rows.

Providing Solutions One Project at a Time

We are honored to facilitate this project. Thank you to Amerliab for choosing AK Material Handling Systems for their warehouse design and relocation. If you need help planning your storage project, call 800-722-5908 or fill out a quote form today. Stay tuned for a phase two update!

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908