Choosing the right type of pallet racking for your warehouse is crucial. If you’re just beginning to fill your warehouse, want to change up your pallet racking, or just need more information on racking terminology, we’re here to give you the 411 on structural pallet rack.

If you are starting at square one, this is for you. If not, you can skip this section.

Structural Pallet Rack: The Basics

From our Pallet Rack Guide: “Pallet Rack is a material handling storage system engineered to store materials and products that are often palletized or bundled. There are many different styles and manufacturers of pallet racking, but all of these share the same goal of increasing storage density by storing pallets off the ground, utilizing vertical space.” Pallet racking is used in areas like large warehouses, distribution centers, manufacturing plants and other storage facilities. Additionally, there are many pallet racking types, as well as add-on accessories.

Now that you’ve got that down, let’s move to specifics. Standard Selective Pallet Racking is the most common style of pallet rack used in warehouses. All standard selective rack consists of upright frames, cross beams, and wire decking. Within selective racking there are two types of steel used: roll formed and structural. These two main types are often, but not always used in different applications. The differences between the two start with are how they’re manufactured. Roll formed racking is made by rolling and cutting sheets of steel, earning it the name “roll formed”. This type of steel is often used in the manufacturing of racking because it’s optimal for creating lengthy products in large quantities. The way this type of steel becomes stronger is by adding more longitudinal bends to the product. Structural racking, on the other hand, is produced by passing a large chunk of hot steel through a roller to attain a specific shape, such as a C-channel or I-beam. Due to its high strength-to-weight ratio, structural steel is often used in the construction of high-rises.

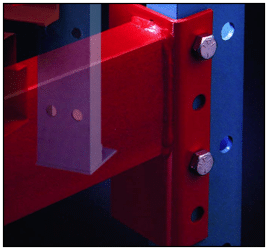

Structural pallet rack. Note the bolt-together design.

Teardrop pallet rack. The beam-to-frame connection consists of pins and teardrop-shaped slots, as well as a built-in safety clip that prevents disengagement

Attributes of Structural Racking

We’re going to break down pallet rack weight capacity:

- Hot molded steel allows the system to be stronger

- Less likely to break down and need replacement

- High weight capacity

- Popular for use in harsh or demanding conditions, such as freezers, fast-paced distribution centers and heavy duty applications

- Better at withstanding impacts from lift trucks

- Used in both selective and custom engineered rack systems (pushback, drive-in, pallet flow and carton flow racking)

Structural Pallet Rack Project Example

Structural Pallet Rack: Design

As mentioned earlier, structural rack differs from roll formed in its construction. Structural racking uses a beam-to-frame connection that’s bolted together, which adds to its already strong design. How this works is that the C-Channel beams are attached to the I-Beams with bolts, creating a system that can uphold a sizable amount of weight. This system is also built to withstand harsh conditions, which why it is often used in environments like freezers, coolers and fast-paced distribution facilities.

Structural steel is found virtually everywhere in densely populated areas, from skyscrapers to bridges, sculptures to parking garages.

Structural racking isn’t right for every application, but is often just the fit for those with very heavy loads. How heavy does the application need to be to require structural steel? The answer to that question varies from project to project, and should be assessed by an experienced Systems Design Specialist. Like roll formed pallet rack, structural racking can be customized in a variety of colors, sizes, and capacities to fit your project’s specific needs.

Save Money Over the Long Term

Although structural racking may be more expensive up front, you will often save money in the long run because of its lengthy lifespan. We often talk about structural racking as being best suited for drive in rack, push back rack, or very heavy load bearing applications. However, one could argue that structural racking is a excellent option for even standard selective rack applications because of its dependability and durability.

Structural pallet rack is often left off the table during the initial quoting process due to it being considerably pricier than roll formed racking. This increase in cost, however, comes with a substantially longer lifespan and more resistance to damage. If a customer plans on using their racking for many years, the higher upfront investment in structural pallet rack could pay dividends in terms of lower maintenance and replacement costs. It’s not uncommon to see structural racking that has been in use for decades showing little, if any, signs of damage or breakdown.

The Takeaways

- Structural pallet racking, though less popular than roll formed pallet rack, plays a vital role in material handling, particularly in heavy duty applications.

- It’s often used in engineered systems like drive in pallet rack and push back rack, but can also be used for standard selective racking.

- The manufacturing process of structural pallet rack differs significantly from roll formed racking. Instead of cold rolling steel, structural pallet rack is formed by shaping hot steel.

- Structural is significantly stronger and more durable than roll formed steel. It’s also costlier. Yet, in many instances, this higher initial cost is recouped over the life span of the racking because it tends to last longer and avoid more damage than roll formed pallet rack.

Is there anything we’ve missed? If so, reach out and let us know!

Interested in learning more about structural pallet rack? Get in touch with one of our Systems Design Specialists for a free consultation

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908