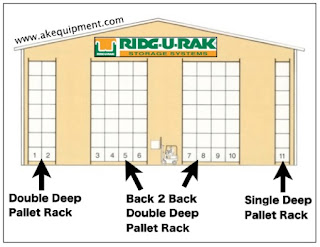

First, let’s clarify the terminology. We are going to explain double deep selective rack. Technically, double deep pallet rack could be done with push back rack or drive-in pallet rack. But, those types of rack are for another discussion.

Double deep selective pallet rack is simply “squeezing” the standard pallet rack rows together to eliminate aisles. The pallets are now stored two deep.

So how do your reach into the rack for storage and retrieval of the pallets?

The answer: double-deep reach trucks. These forklifts are modified versions of the standard narrow aisle reach truck that operates in 8’ to 9’ typical aisle widths.

In general, up to a 40% increase in pallet positions can obtained. Warehouses that have high throughput will consider double deep rack as a good option as it offers good selectivity and high-density storage. In addition, since standard pallet rack is used, the rack is relatively inexpensive for high-density storage. The cost drawback is in the specialized forklift.

In summary, warehouses with multiple pallets per SKU should always at least consider the benefits of double deep selective rack. For more information on double deep pallet rack or for a quote call 800-722-5908 or Contact Us.

By: Senior Warehouse Design Specialist Brian Koski

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908