For warehouse managers and enterprises gearing up to enhance their storage capabilities, this article serves as a practical guide, offering actionable strategies and methodologies for success. Drawing from some of Iowa’s leading warehousing models, we present a roadmap to optimizing warehouse operations. Follow along and contact us for more information!

Smart Warehousing in Iowa

In Iowa, companies like Nestle in Agriculture & Food Processing, and CNH Industrial in Manufacturing, are trailblazers in warehouse design. Each brand’s unique journey in warehousing offers invaluable lessons for others in similar sectors.

Nestle: Revolutionizing Agriculture & Food Processing

Nestle, with operations in Davenport and Burlington, exemplifies excellence in warehousing. Implementing push-back racks for pet food processing, they’ve optimized storage efficiency. Nestle’s approach demonstrates a balance between maintaining product quality and embracing safe and modern storage methodologies.

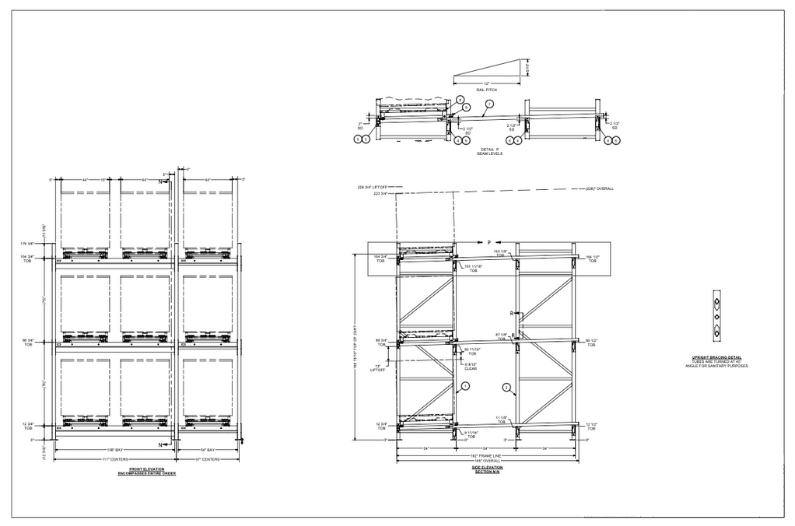

“This Steel King push-back racking was a bolted, structural tubing system that maximized pallet storage in a small production area. The closed tubing design promotes cleanliness in food processing facilities because there are no additional holes in the columns to trap hard-to-reach dust and debris.”

Nestle Warehouse Design

CNH Industrial: A Manufacturing Marvel

Mallard Dyna-Flo Carton Flow Racking

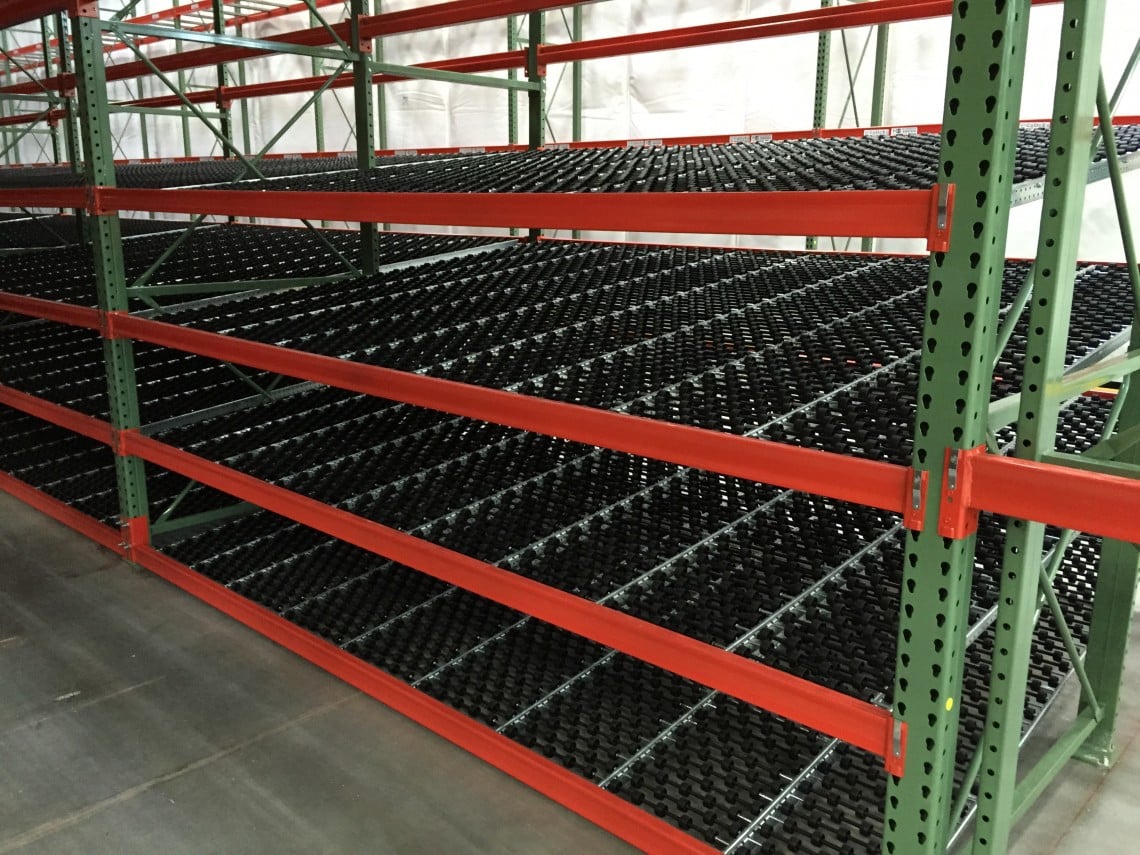

CNH Industrial stands out in the manufacturing landscape. Their Burlington site showcases a commitment to efficiency, employing Mallard Dyna-Flo carton flow racking for heavy equipment manufacturing. CNH Industrial’s strategy underscores the significance of tailor-made storage solutions for diverse industry needs.

CHN Industrial primarily worked with AK to add carton flow to their existing racks for assembly and parts storage to support production.

“We provided over 200 levels of Mallard Dyna-Flo carton flow for this client. This full-coverage wheel bed style offers elite flexibility to create various lane widths to store boxes and cartons of any size.”

Key Strategies for Warehousing Success

- Adapt Industry-Specific Racking Systems: Choose racking solutions, such as push-back and carton flow racks, that align with your sector’s unique requirements.

- Embrace Quick-Shipment Solutions: In today’s fast-paced environment, prioritizing swift solutions for immediate project needs is essential for staying competitive.

- Integrate Advanced Technologies: Implement technologies like warehouse robotics, ASRS, and conveyor systems to enhance efficiency and accuracy.

Complying with Standards

Compliance with warehouse safety standards such as OSHA rack capacity labeling requirements is crucial. This ensures safety and operational efficiency, a practice embraced by Iowa’s warehousing sector.

Adopting industry-specific racking systems, prioritizing quick-shipment solutions, and integrating advanced technologies are key to elevating warehouse efficiency. By following the footsteps of leaders like Nestle and CNH Industrial, any warehouse can transform into a hub of efficiency prepared to meet the demands of modern storage challenges.

Call 800-722-5908 or fill out a quote form to begin a custom warehouse design solution for your facility today!

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.