What is Push Back Rack?

Push Back Pallet Rack utilizes wheels in the rack structure. This type of pallet rack system allows palletized goods and materials to be stored by being pushed up a gently

Why Push-Back?

As budgets remain tight, proper space utilization becomes a must for all warehouses. Push back pallet rack increases the amount of pallets that can be stored and also offers more pick faces than typical high-density systems. When an average number of pallets per part or product exceeds five in quantity, push back systems become more justified. Push back pallet rack can offer 100% more storage than standard selective pallet rack and can also offer a solution to the honeycomb effect of standard high-density drive-in pallet storage systems.

Below is a helpful tool we use to help our clients identify the correct system for their applications.

10 Things to Know about Push-Back Pallet Rack:

- Compared to standard selective pallet rack many forklift operators think push back pallet rack is easier to load and unload.

- Rack damage is minimized because lift trucks never enter the rack system.

- Push back aisles usually only need to be 6″ larger than your manufacturers’ minimum aisle requirement.

- Push back is a low-maintenance pallet storage rack system.

- Most standard forklifts can be used with a push back rack system.

- Standard push back systems are designed to hold a max pallet weight of 3000 lbs but can be designed for heavy load ratings.

- Standard GMA pallets are most commonly used in push back systems although systems can be designed to hold other styles and size pallets.

- Push-back will require more height per level than selective rack- typically 6-8″

- Hybrid systems are commonly used (i.e drive-in on floor level- push-back on the upper levels

- Structural Rack is preferred and often required for push-back systems.

How Much Does Push-Back Pallet Rack Cost?

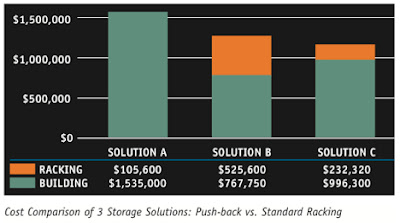

COST COMPARISON

Standard Warehouse, $50./sq. ft.*

Solution A – 30,750 sq. ft. total

-> 2640 pallet positions of standard

racking- Solution B – 15,375 sq. ft. in total

-> 2628 pallet positions of push-back

racking - Solution C – 19,926 sq. ft. total

-> 2676 pallet positions, 300 in

standard rack, 1332 in push-back, and 1044 in floor storage

*Freezer warehouse would average $100./sq. ft.

* Table and cost comparison information taken from Excel Storage Products Push back literature

If you would like more information call us at 800-722-5908 to get in touch with one of our design experts.

Sources:

Excel Storage ProductsRidg-u-rak

Wikimheda.org

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908