Early Dexion pallet racking. Source: Wikipedia

In its early stages, pallet racking varied widely in terms of its structure, strength, quality of materials, and other parameters. This pallet rack identifier lists 39 different styles and manufacturers of pallet rack, and that’s just the tip of the iceberg.

Many manufacturers created proprietary designs to ensure customers would return for business when they needed to add or replace components.

In the present day, there are still many manufacturers producing proprietary pallet rack components that aren’t compatible with other types of racking.

Teardrop Pallet Rack

There are two main types of pallet rack in production today.

Roll-formed pallet rack is the more popular of the two, the product of cold rolling steel sheets into upright frames and beams.

The other type is structural pallet rack, a stronger type of pallet racking formed by casting molten steel.

Of the roll-formed pallet rack available on the market, the teardrop pallet rack is by far the most popular design.

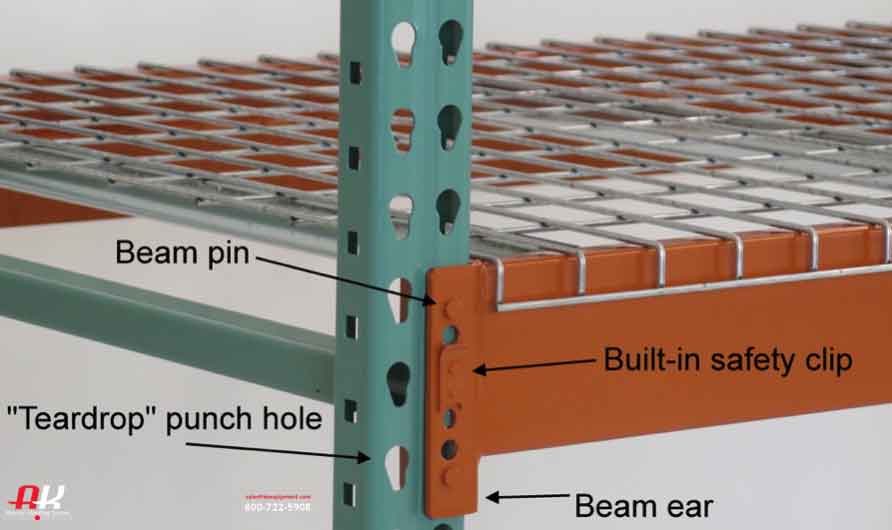

The name “Teardrop” refers to the shape of the punch holes in the racking’s upright frames. The punch holes resemble an upside-down teardrop, a design that makes the beam-to-frame connection more secure.

Instead of sitting loosely in the upright frame, this design allows rack beam rivets to fit more snugly in the teardrop upright slots, as the tapered shape creates more friction.

As shown in the image below, the beam pin, or rivet, is inserted at the top of the teardrop and pushed down towards the bottom where the opening is tapered.

As with most rivet shelving, pallet rack installers often need to hammer teardrop beams with a rubber mallet to lock them fully into place. Despite this, many of the beam ears manufactured today include built-in safety pins, which lock the beam into the upright frame.

These locking pins prevent beams from disengaging the upright frame during loading or unloading. For older beams that lack this safety feature, it’s highly that users install pallet rack safety pins to prevent potentially dangerous accidents.

Teardrop Pallet Racking Compatibility

One of the primary benefits for users of teardrop pallet rack systems is its almost universal compatibility with other teardrop brands.

Thanks to market forces and a variety of other factors, most racking in production today features a “universal” teardrop design. This means that a person buying replacement or add-on components doesn’t necessarily have to buy from the same manufacturer when adding on to their current racking.

It also provides more flexibility when buying used pallet rack. This is because components from different manufacturers can be purchased and used together.

However, there are a couple of exceptions and rules of thumb to keep in mind when combining racking from different manufacturers.

Be Careful Using Different Manufacturers’ Beams in the Same Bay or Beam Level

Although Manufacturer A and Manufacturer B may both produce 96” teardrop beams that look exactly alike, there can be subtle differences between the two.

A 96″ beam, for example, is not necessarily 96″ long. In reality, it may be 96.25” or 96.5” inches.

This may not sound like much of a difference, but it is. If two beams of even slightly different sizes are used in the same beam level or bay, it can cause warping and reduce the structural integrity of the pallet rack.

Different manufacturers’ products also typically have different weight capacities, which can spell trouble for warehouses combining brands in the same rack storage system.

It’s also important to be careful using different manufacturers’ components together because it often voids the warranty. If there’s an accident that involves two different manufacturers, neither is likely to accept responsibility for any damage that occurs.

When it comes to mixing pallet rack brands, users should be aware that they may have to accept responsibility for any accident or equipment failure involving the pallet rack.

Questions about Teardrop Style Pallet Rack?

Do you have questions about teardrop pallet rack or other material handling-related topics? Reach out and let us know. We’ll be happy to help and may answer your question as a blog or video post.

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908