In the bustling industrial landscape of Illinois, warehouse managers and companies are working toward heightened efficiency and smarter operations. This page offers comprehensive strategies and success tips, drawing from some of Illinois’ sophisticated warehousing practices.

From the vibrant cityscape of Chicago to the serene streets of Lexington, Illinois, lies a canvas of diverse industrial needs and innovative storage solutions. Gustave A Larson in Wholesale & Distribution and Pioneer Plastics in Manufacturing are examples, each embarking on a unique path to optimize their storage and operational efficiency.

Gustave A Larson: Exemplifying Distribution Mastery

In the world of HVACR wholesale distribution, Gustave A Larson has established a benchmark at its storefront in Chicago, IL, with its Steel King selective pallet rack and Triboro closed shelving systems. Their strategic choice of storage solutions not only proves their dedication to operational excellence but also highlights their agility in responding to the dynamic demands of wholesale distribution.

Gustave A Larson worked with AK Material Handling Systems to relocate from one storefront to another. Warehouse relocation projects require time, strategy, and space planning to make the most efficient use of resources. Oftentimes, facilities need to remain in full operation throughout the move, so the ability to plan around a working warehouse is crucial.

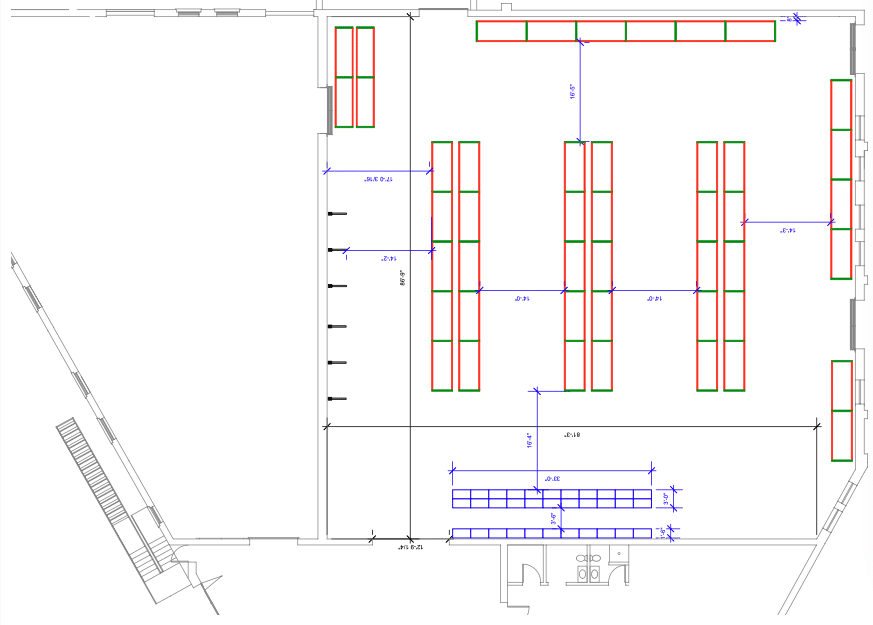

Gustave A Larson Warehouse Design Drawing

“We relocated about 50% of their original racking and provided them with additional selective racking for large components like AC units, furnaces, and hot water heaters, and closed shelving for small parts and piping.”

Selective pallet rack systems and shelving, like those selected by Larson, offer numerous benefits for HVACR wholesale distributors, significantly enhancing their warehouse operations. Here are three key advantages:

- Efficient Space Utilization: Selective pallet racking is designed to maximize storage space in a warehouse. By allowing for vertical storage, it enables HVACR distributors to store more products in the same footprint. This system is particularly beneficial for managing a wide range of inventory sizes and shapes, typical in HVACR distribution, ensuring that every inch of warehouse space is optimally used.

- Versatility and FIFO Management: This racking system is inherently versatile, accommodating a variety of pallet sizes and types. It’s especially conducive to First-In, First-Out (FIFO) inventory management. Selective pallet racks allow easy reconfiguration and adaptation to different product lines, facilitating efficient stock rotation and access.

- Ease of Access: With direct access to each pallet, selective pallet racking simplifies the process of storing and retrieving items. This is crucial in a fast-paced HVACR wholesale environment, where quick access to products can significantly expedite order fulfillment and reduce wait times. The ease of access not only streamlines operations but also reduces the risk of damage to goods during handling, contributing to overall operational efficiency.

Pioneer Plastics: Sculpting Efficiency in Manufacturing

Pioneer Plastics’ journey in the manufacturing sector is illuminated by its adoption of selective pallet racking and flush mount wire decking. This move demonstrates the company’s commitment to both precision and adaptability, ensuring their products are not just high quality but also efficiently stored and managed. Selective pallet racks and flush mount decking are ideal for plastic injection molding manufacturers like Pioneer Plastics in Lexington, IL, because they provide:

- Streamlined Storage for Diverse Molds: Selective pallet racks provide accessible and organized storage for varied mold sizes and shapes in plastic injection molding. This system ensures molds are well-protected, easily retrievable, and orderly, enhancing the integrity and smooth operation of the manufacturing process.

- Improved Inventory Management Efficiency: Selective pallet racks offer enhanced visibility and accessibility for inventory management in plastic injection molding. This system facilitates efficient tracking and handling of materials, reducing downtime and boosting manufacturing efficiency, which is crucial for maintaining tight production schedules.

- Safe and Unobstructive: Flush mount wire decking sits within the beam level to avoid any overhang into the aisles. This prevents bumps and nicks and ensures smooth operations throughout the facility.

“We were able to supply the client with the racking sizes they were looking for and were able to supply the product in 3-4 days even with the larger quantities in this order.”

Quick ship is an essential offering that benefits projects, big or small, that are happening within a specific timeline.

These case studies from Illinois serve as an example for industries ranging from manufacturing to automotive and food & beverage sectors. They emphasize the significance of tailored solutions like selective pallet racks, shelving, and relocation services, crucial for meeting the varied demands of these industries.

Quick response to project needs is another hallmark of Illinois’ industrial pioneers. The ability to deliver rapid solutions is indispensable in today’s fast-evolving market landscape. This agility is especially crucial for companies like those in the automotive manufacturing and food & beverage industries, where time is often a critical factor.

Technological integration is a cornerstone of Illinois’ warehousing strategy. Innovations such as warehouse robotics, Automated Storage and Retrieval Systems (ASRS), and shuttle systems are reshaping the way warehouses operate, bringing in an era of unprecedented efficiency and accuracy.

When planning your next warehouse or updating an existing warehouse, be sure to:

- Select racking systems that align with your industry’s specific requirements.

- Utilize quick response and immediate shipping solutions for urgent project needs.

- Harness technology to elevate accuracy and operational efficiency.

By adopting the strategies employed by Gustave A Larson and Pioneer Plastics, warehouses can evolve into highly efficient, technologically advanced facilities, poised to meet the storage demands of the future. Call 800-722-5908 or complete an online quote form to get started on your custom warehouse design solution today!

Let’s Talk

Ready to get started?

Or have questions about any of our products or services?

Fill out the form and a representative will contact you promptly.