When talking with customers, one of the first questions we ask is how much they need their pallet racking to hold. It’s one of the fundamental pieces of information that will help us provide the right solution for their needs and make sure their setup is safe.

We’re going to break down pallet rack weight capacity:

- Pallet Rack Capacity

- Overestimating Capacity Needs

- Calculating Your Capacity Needs

- Pallet Rack Capacity Labels

Pallet Rack Capacity

Imagine you’re comparing beams from different manufacturers. Manufacturer A might make a certain size beam with a given capacity while Manufacturer B may produce a beam that, even with similar dimensions, holds less. Apples-to-apples? Not always.

Even if you’re not comparing different types of pallet rack, you still want to make sure you’re getting racking that’s strong enough to meet your storage needs. If you decide to ballpark the capacity you’ll need instead of taking time to do the necessary calculations, you can end up with numbers that are way off. It’s easy to underestimate the amount of weight you’ll need your racking to hold and end up with material handling equipment that’s not suited for the application. That’s at best a risky situation and at worst a very dangerous one.

Overestimating Capacity Needs

On the opposite side of the spectrum, you don’t want to have overkill on your rack system capacity because it could end up costing you thousands of dollars. How so? Vertical storage space is extremely valuable. Generally, higher-capacity beams have taller profiles, also known as the “beam face.” These taller profiles literally use up vertical real estate. In today’s warehouses, space is money. Using beams that are too heavy-duty for your needs is wasteful and prevents your operation from reaching its efficiency potential. Let’s look at the example below.

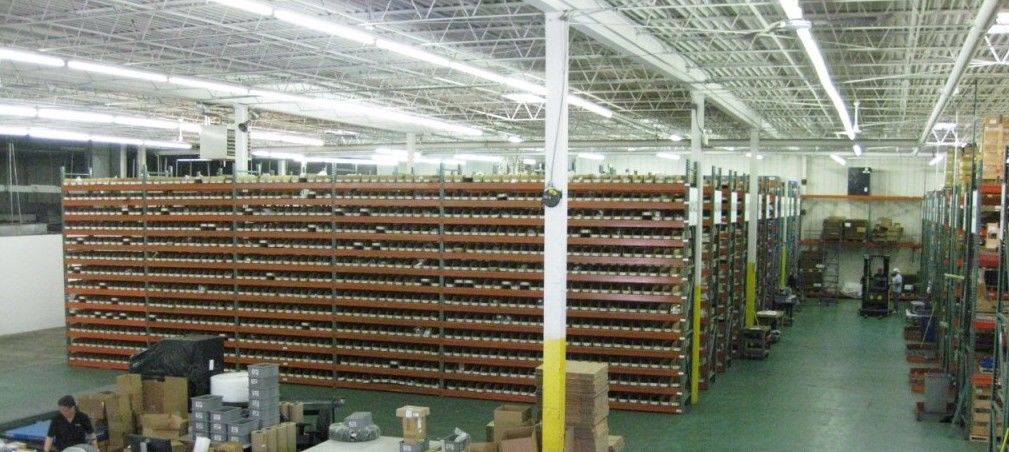

This warehouse is storing plastic bins on cross beams that most likely have a shelf capacity of over 6000# per pair. Needless to say, they will never use all of that capacity. The pallet rack beams are taking up an extreme amount of vertical shelf space. With a 5″ cross beam face and 13 shelf levels, almost 5′ of vertical spaceis being used up by the beams. If they had opted for lighter-duty 2.5″ beams, they would have had over 3′ of additional real estate they could use to store more inventory.

Lighter duty loads require lighter duty beams. This warehouse could have saved several feet of vertical space by using beams with a shorter profile.

Calculating Your Pallet Rack Capacity Needs

While calculating your capacity needs is fairly straightforward, we still recommend getting in touch with a material handling professional to confirm your calculations. They’ll have important considerations and information. That said, here’s how to get started:

- Start with the heaviest possible load you’d be storing in a given pallet position. For this example, we’ll say 2,500#.

- Multiply this number by the number of pallet positions per beam level. In our example, we’ll assume we’re working with 96″ beams and that the number of pallet positions per beam level is 2. Now we know that that we’ll need a beam capacity of at least 5,000#

- In most situations, you’ll only need steps 1 and 2. In a select few, you may also need to factor in upright frame capacity. Frame capacities change as the height between beam levels grows or shrinks, making them more complicated. When talking upright capacities, you’ll want to consult a material handling expert.

Pallet Rack Capacity Labels

Once your racking is set up, we advise putting capacity labels on it so forklift operators are aware of weight limits. Pallet rack capacity labels are customizable to your racking and are highly-visible reminders that improve warehouse safety. We’re happy to work with you to produce pallet rack capacity labels for your warehouse. Before you call, make sure you have some of the following information: rack manufacturer, beam sizes (beam face and length), upright frame size (height & column size) and any additional product numbers or identification available.

Need Help Finding the Right Pallet Rack Capacity?

If you’re not sure how to calculate your capacity requirements, remember, you don’t have to do it alone. If you’d like help figuring out your rack requirements, contact us or give us a call. It’s always best to have a pallet rack expert on your side helping you along the way.

Warehouse Safety Helpful Resource: OSHA Materials Handling & Storage

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908

Let’s Talk

Ready to get started? Or have questions about any of our products or services? Fill out the form and a representative will contact you promptly.

About AK Material Handling Systems

We deliver value to our customers by providing the absolute best combination of quality products, helpful customer service and competitive pricing. We specialize in warehouse layout & design, pallet rack systems, engineered sales, mezzanines, modular offices and completed turn-key warehouse systems. For more information email us or call (800) 722-5908